Porch & Veranda Finishing Touches

To complete your new beautiful Fine Iron porch or veranda we offer a selection of high quality finishing touches that are either made by our skilled craftsmen or are produced by carefully selected suppliers.

Spandrels

Spandrels (sometimes called brackets or gallows) are designed to give extra strength to the construction and also to make the overall aesthetic pleasing to the eye. Spandrels for our porch and veranda ironwork are available in six designs and three typical sizes of 360 x 360mm, 460 x 460mm and 560 x 560mm.

Though we do always recommend having spandrels, depending on the type and size of structure chosen they are not always required. All of our cantilever door canopies require spandrels for structural support and the size of the brackets will depend on the overall dimensions on the canopy.

If you would like a custom spandrel design or size please don’t hesitate to get in touch.

Rose Leaf

This organic design spandrel was created to compliment our Roseleaf ironwork design and features the same cast leaf detail. However it can be paired with any of our designs including columns for a more decorative or romantic feel.

Queen Anne

Although it share’s it’s name with our Queen Anne design frieze panels and uprights, this beautiful spandrel design with its perfectly proportioned curves would also compliment our columns as well as the Eden, Nouveau, Henley and Quatrefoil designs.

Sun Ray

Our most popular spandrel design, the sunray works equally well on traditional and more modern porch, canopy and veranda ironwork designs.

Ring

Another popular choice, this design takes inspiration from the masters of ironwork – the Victorians! The spandrel works well with most designs, but we particularly love it paired with our Victorian style Windsor columns, our Ring Canopy design or the Nouveau Porch ironwork.

Scroll

Scrolls in ironwork became popular for their elegant, timeless design and the way they balance strength with graceful, flowing curves inspired by nature. This spandrel design is perfect for those looking for a more traditional style of wrought ironwork.

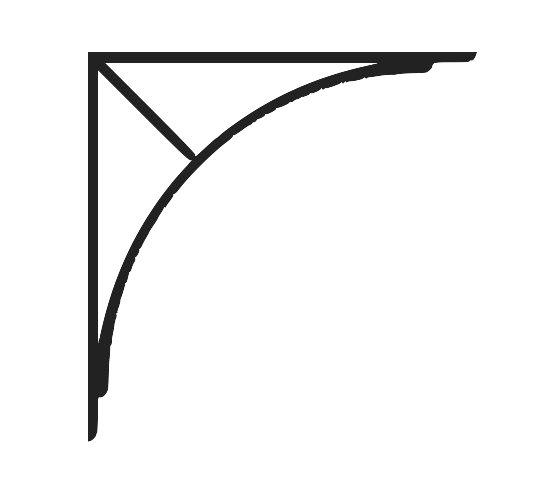

Contemporary

For those who believe less is more – our contemporary spandrel is simple and unfussy and can work with any design, however designs in keeping with this understated metal bracket include the Highbury, Cambridge, Regency Light and our Windsor column.

Paint & Protection Options for External Ironwork

Our expertise and experience in ironwork finishing ensure a durable, authentic, and beautiful finish that will protect your ironwork for years. We continuously invest in the latest technology, machinery, materials, and processes to deliver the highest quality wrought iron products to our customers.

Advanced Spray Shop Technology

Our custom-built spray shop is designed to produce exceptional results – here’s how:

- Temperature-Controlled Curing Room: Ensures consistent curing, regardless of weather conditions.

- Ventilated Paint Room: Equipped with a state-of-the-art filtration system for a flawless application.

- Efficient Drying System: Custom-built drying racks and climate controls provide the optimum temperature for drying and hardening painted ironwork effectively.

Our Finishing Process

- Proper Preparation: Our skilled craftsmen carefully clean off welds and remove spatter from your ironwork. We then shot-blast the metal to achieve perfect adhesion.

- Three-Coat Two-Pack Paint System: This high-quality system creates a weather-resistant, durable finish that stands up to the elements. We use a satin black paint as standard, a timeless choice for ironwork.

- Custom Color Matching: We offer matching services for most RAL colors and popular paint brands like Farrow & Ball or Dulux. (Note: Custom colors incur a small additional charge.)

Extra Protection for Harsh Environments

If your project is located near the coast or in an exposed area, we recommend our in-house zinc thermal coating system for enhanced protection. This modern alternative to galvanizing has several advantages:

- No Thermal Distortion: Unlike galvanizing, our process minimizes the risk of warping.

- Exceptional Durability: The zinc coating bonds with the steel, creating a protective layer that can last over 20 years. Coating lifespan depends on factors such as air pollution, humidity, and proximity to the coast or certain building materials.

We adhere to the BS EN ISO14713 standard, with our standard zinc coating at 120 microns. This provides a typical life to first maintenance of 5 to 10 years. For even greater protection, we can apply a thicker coating on request. Download PDF file for more information about Zinc Metallisation and its sustainability (recycling).

.

Thoughtful Touches for Long-Lasting Beauty

To help maintain your ironwork:

- Touch-Up Paint Included: Each order comes with a small tin of touch-up paint to rectify any chips or scratches which can occur during installation as well as covering the heads of any visible fixings.

- Care & Maintenance Guide: Simple guidelines are provided to keep your ironwork looking pristine. Periodic maintenance is recommended, much like other features in your home.

Cast Shoe Covers

Our cast shoe covers are sand cast at our foundry in Wales, they cover where the uprights affix into ground providing a clean finish to the base of the decorative ironwork. They can be used with or without our natural stone plinths.

Our corner and double cast shoe covers have been designed for use with our typical 180mm wide uprights with the single cast shoe covers being available for use on the Regency Wide and Arden design ironwork.

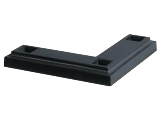

Cast corner base shoe

Cast double base shoe

Cast single base shoe

Regency Light Porch With Natural Stone Plinths

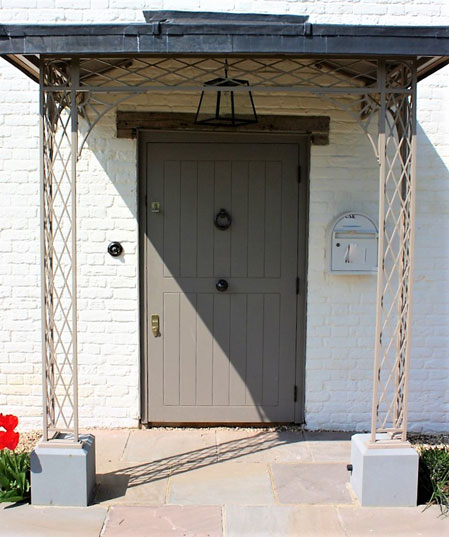

Treillage Porch With Natural Stone Plinths

Natural Stone Plinths

Our stone plinths are hewn from Forest of Dean stone. They are then dressed and drilled by Welsh stonemasons very near to our workshops. Please note that colour may vary with natural stone. The stone is darker when first quarried and will lighten with natural oxidisation.

If you would like to add stone plinths the height of the decorative wrought iron uprights will be adjusted accordingly to suit.

Hand hewn stone plinth

Stone Plinth with Corner Shoe

Custom Veranda Enclosure

If you would like the option of enclosing your new Fine Iron veranda to extend the use and enjoyment of your ironwork through wetter and colder months, we are able to supply a tailor made cover with options to personalise colour, door openings and large windows so that your view to your outside space remains unobstructed. This is removable allowing you the freedom to open up the veranda during summer months!

Veranda With Custom Enclosure

Looking Out From A Veranda With Custom Enclosure

We can also provide bespoke fitments for your new ironwork, so please do not hesitate to contact us for advice or estimates regarding special requirements.

How does it work?

Frequently Asked Questions

How can I contact you?

There are many ways to contact us and we are always happy to help! You can contact us via the contact page on our website, you can email us directly (info@fineiron.co.uk), or can telephone us during our normal working hours on 01874 636966. Our opening hours are 9am to 4:30pm Monday to Friday. You can also find us on Facebook, Pinterest, Houzz and Instagram.

Do you have a showroom?

Where can I find designs, styles and more information about your Porches, Verandas and Canopies?

We offer a wide range of metalwork designs and styles to suit any property– for ironwork as individual as you! You can find more information about our range of porches, verandas and canopies including our typical sizes. All of our ironwork designs and roof options can also be viewed in our online brochure, which can also be downloaded as PDF.

What materials are your products made from?

For materials used for roofing please see ‘What roof options are available?’

What colours can I have my finished ironwork?

Are you able to galvanise – I live near the coast.

What is Zinc Thermal Coating? When is it recommended?

What do you need to know in order to provide me with my personalised estimate?

Ok, so here is what we need to know: -

Some basic contact information including your name, email address, telephone number and the address.

If you are able to send a photo of where the ironwork is to be installed this can be extremely useful – ‘a picture is worth a thousand words’ as they say.

Approximate dimensions these must include the width, the depth out from the building and the height to the underside of the roof. (Click to see example image)

The design of ironwork you would like, whether it is one of our existing designs or you have been inspired by a design you have seen elsewhere

The type of roof you would prefer and any accessories you would like to finish your ironwork off – such as cast shoe covers or our forest of dean stone plinths (please see our brochure for more information about the options available)

Do you install the ironwork?

What are roof options are available?

(We offer an array of roof options to give you the freedom to choose what you prefer. Our most cost-effective option would be our galvanised mild sheet roof (see below for more information about this type of roof).

We can provide a roof framework which can be lined and leaded by your local roofer/ builder – we do not line and lead ourselves as we are not a roofing company and there are many styles of lining and leading, which are best worked through with a professional in that trade.

We also offer a glazing bar roof, which allows you to have a partially or fully glazed roof, this can be straight or curved with hipped ends. We do not supply the glass as we are not a glazier, but do supply the mild steel sheet for infill panels if required.)

Can you attach guttering to a galvanised mild sheet roof?

Can you line a galvanised mild sheet roof?

Can you flash around the galvanised mild sheet roof using lead or similar?

How will my order arrive?

We take the utmost care when packing and your pallet will be made specially for your ironwork. However, we would always ask that the ironwork is unpackaged and inspected before the courier leaves. In the extremely rare event of any damages we would ask that you make us aware of this as soon as possible and send any relevant photos. (All of our Ironwork is photographed prior to leaving our workshop)

Is there a delivery charge?

Do prices include VAT?

Do you keep any stock?

Can I return my order if I don’t like it?

All of our Porches, Verandas and Canopies are handcrafted to order to your chosen design and specified dimensions. Fully dimensioned drawings will be provided for you and/ or your architect/builder to sign off before the commencement of any work. This being the case we cannot take returns. In the unlikely event that there is a fault or error with the ironwork please contact us immediately. For further details please see our terms and conditions of sale.

What is your lead time?

What is included with my ironwork?

If you or your builder have any queries when installing our ironwork, we are always on the end of the phone and are more than happy to help in any way we can!

What maintenance is required if any?

All of our ironwork is constructed using the best materials and the highest standard of manufacture and with a little maintenance will last you for decades. For more information about maintenance, please see our ‘caring for your ironwork’ page.

As with any natural product that has been painted for protection, particularly one that spends its life outside, ironwork does require periodic inspection and a little maintenance in order to keep it looking beautiful.

This is a very easy process:

- We recommend a full visual inspection 6 – 10 weeks after installation to ensure there is no discolouration/oxidation from water ingress which may occur in some of the tighter joints, or from chips/scratches that may have been missed initially.

- Frequency of subsequent inspections/maintenance will depend very much on local conditions but should be at least annually.

- Any debris, leaves etc. should be cleared to prevent water getting trapped and sitting against the ironwork.

- The ironwork should be wiped over with a damp cloth intermittently to remove any dust/dirt.

- Any chips/scratches that occur in use should be touched up as soon as possible before oxidation occurs. We appreciate that you may not spot them straight away so if oxidation has already occurred, this can easily be remedied by gently and carefully rubbing back the affected area with a light abrasive pad/Scotch pad (such as those on the back of a washing up sponge), applying a proprietary rust inhibitor and touching up with the paint provided. Step by step instructions on how to do this are available on our website.

Installation - How to handle my ironwork?

Thank you for purchasing your new ironwork from Fine Iron. We want to ensure you are completely happy with your ironwork and it remains as pristine as when it arrived for many years to come.

In order to do that, please follow these simple guidelines:

- The ironwork should be unwrapped on arrival in order to check the goods. If you do not intend to install the ironwork immediately it can be tempting to leave it wrapped for protection – please do not do this (refer to packing and delivery instructions for further information).

- The ironwork components are very heavy. If they are placed directly on or against a hard surface (e.g concrete, brick, stone, paviours), either when unpacking, when storing it after unpacking prior to installation, or during installation, the weight if the ironwork on/against the surface can damage the paint finish. The damage to the coating may not be easily visible so you may not even think it requires touching-up with the paint provided but after a time oxidisation will occur and orange staining will become apparent on the surface. To prevent this happening, please ensure a suitable buffer is placed between the ironwork and any hard surface – this could be cardboard, a lint-free material or similar.

- It is preferable not carry out any cutting/welding works, or any work that creates sparks or debris travelling at high speed, in the proximity of the ironwork but if this is unavoidable, please ensure you provide suitable protection and cover the ironwork beforehand. Sparks and debris will embed in the surface of the paint which are then highly likely to cause oxidation/rust to form.

- Once installation is complete, wipe the ironwork over with a damp, lint-free cloth to remove any dust/dirt (this will also help you to spot any chips or scratches).

- Chips and scratches to the ironwork will invariably occur during the installation process. This is perfectly normal and we provide small tin of paint with every order to enable these to be touched up (this can also be used to paint the heads of the fixings). Touching up should be done immediately or as soon as practicable following installation before any oxidisation occurs.

- We recommend a full visual inspection 6 – 10 weeks after installation to ensure there is no discolouration/oxidation from water ingress which may occur in some of the tighter joints, or from chips/scratches that may have been missed initially.

- In the unlikely event oxidation/discolouration occurs, this can easily be remedied by gently rubbing back the affected area with a light abrasive pad/Scotch pad (such as those on the back of a washing up sponge), applying a proprietary rust inhibitor and touching up with the paint provided. Step by step instructions on how to do this are available on our website.