staircase and Balustrades Glossary

Welcome to our comprehensive, visual Staircase Glossary – a go-to resource for understanding the terminology and key terms related to staircase design, construction, and components. Whether you are a homeowner, a design professional, or a curious enthusiast, this glossary aims to demystify the language surrounding staircases, empowering you with knowledge and understanding.

Staircases are not merely functional elements within a building; they are architectural features that can elevate the aesthetics of any space. From grand and elaborate designs to sleek and modern styles, staircases come in a wide range of forms and materials. However, navigating the world of staircases can be daunting without a grasp of the specialized terminology.

In this glossary, we have compiled an extensive collection of stair-related terms, offering clear definitions and explanations along with 3D visualizations of what each term relates to to help you gain a deeper understanding of the intricate components and construction techniques.

A

Alloy – Aluminium – Ascending Volute – Atrium

Alloy

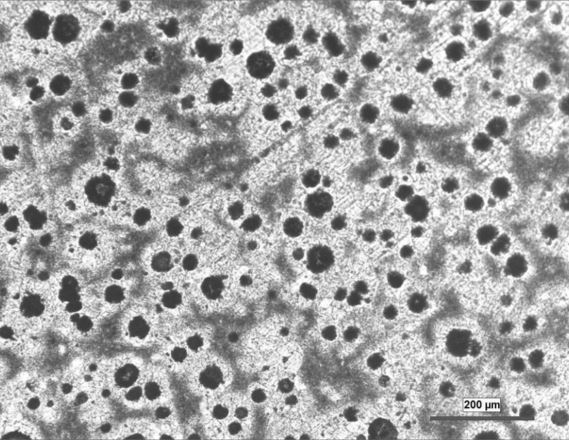

An alloy is a solid mixture or combination of two or more metallic elements or a metallic element with a non-metal element. Alloys are created by melting and mixing the components together, resulting in a material with distinct properties different from those of the individual elements.

Alloys are widely used in various industries due to their enhanced characteristics compared to pure metals. By combining different elements, engineers and metallurgists can tailor alloys to possess specific desirable properties such as increased strength, improved resistance to corrosion, enhanced conductivity, or altered melting points.

The composition of an alloy can vary, and the properties it exhibits depend on the types and proportions of the constituent elements. Common examples of alloys include steel (iron combined with carbon and other elements), brass (copper and zinc), bronze (copper and tin), and stainless steel (iron, chromium, and other elements).

Alloys can be categorized into two main types: substitutional alloys and interstitial alloys. In substitutional alloys, the atoms of the different elements replace or substitute each other in the crystal lattice structure, while in interstitial alloys, smaller atoms fit into the interstices or spaces between the larger atoms.

The use of alloys provides numerous advantages in practical applications. They offer improved mechanical properties, increased durability, resistance to wear and corrosion, and the ability to withstand extreme conditions. Alloys are widely employed in the manufacturing of various products, including automotive parts, aircraft components, electrical wiring, coins, jewelry, and construction materials, among many others.

Aluminium

Aluminium is a versatile metal known for being lightweight, malleable and resistant to corrosion.

It possesses several advantageous characteristics – It is lightweight thanks to its low density, making it significantly lighter compared to other metals. This quality is particularly beneficial in applications that require weight reduction. Aluminium exhibits a favorable strength-to-weight ratio, despite its lightness. By alloying it with other elements, its mechanical strength can be further enhanced. Additionally, aluminium naturally forms a thin oxide layer on its surface, providing inherent resistance to corrosion. This makes it highly suitable for outdoor and marine applications. It is highly ductile and easily shaped, allowing for the production of complex designs. Moreover, aluminium is an excellent conductor of heat and electricity, making it valuable in electrical and thermal applications. Lastly, aluminium is 100% recyclable without compromising its properties, making it an environmentally sustainable material choice. Due to these characteristics, aluminium finds wide applications in industries such as transportation, construction, packaging, electrical engineering, and consumer goods.

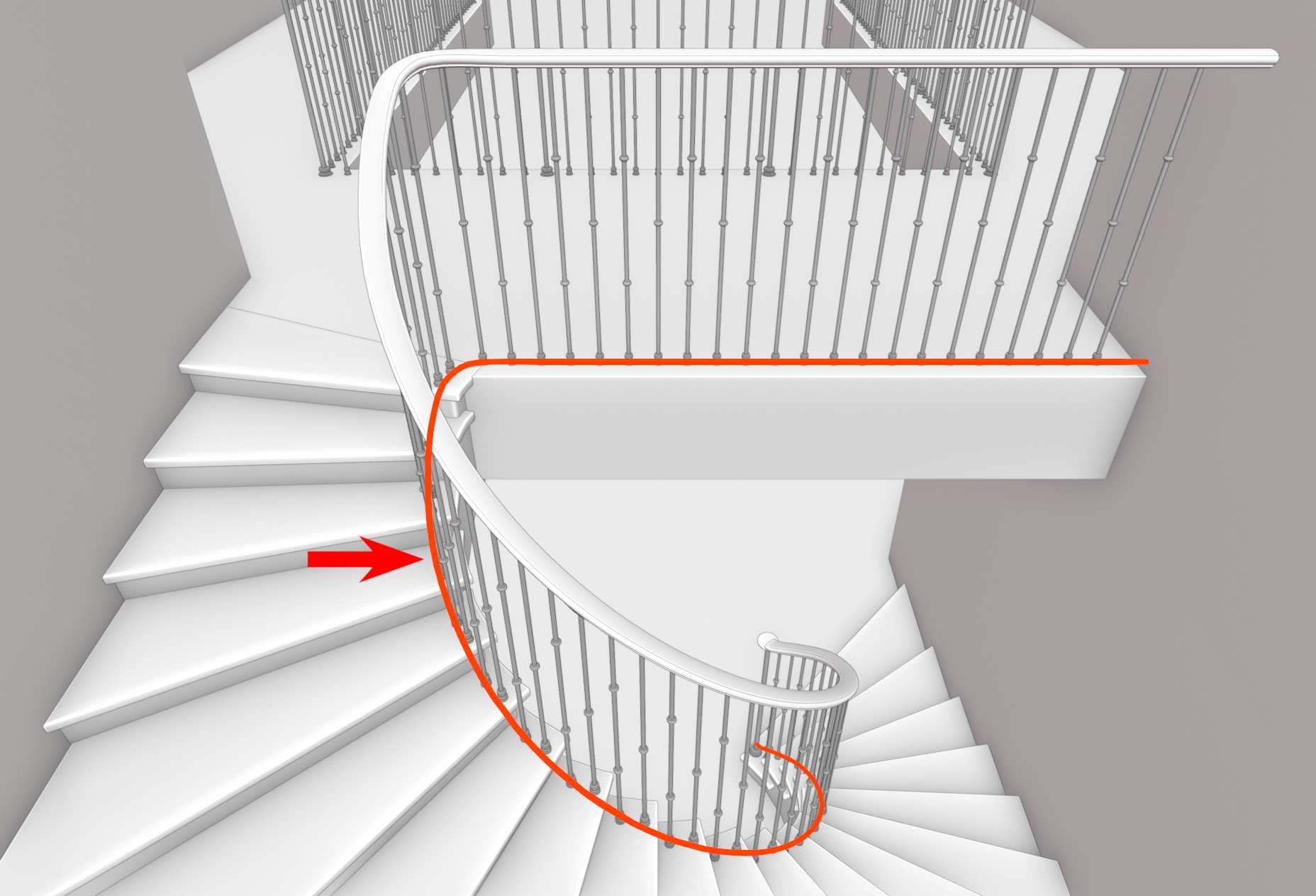

Ascending Volute

(see Monkey Tail) The ascending volute is typically positioned on the side of the handrail facing away from the staircase, and its purpose is both functional and ornamental. Functionally, it provides a smooth and graceful transition for the handrail as it curves upwards from the newel post, offering a comfortable gripping surface for individuals using the staircase.

Aesthetically, the ascending volute adds visual interest and elegance to the staircase design. It is a characteristic feature of certain architectural styles, particularly in classical and traditional designs. The shape of the volute resembles a scroll or spiral, often with intricate detailing and craftsmanship. The volute may be sculpted or carved from wood, molded from metal, or even crafted from stone, depending on the materials used in the construction of the staircase.

In addition to its decorative appeal, the ascending volute can be seen as a design element that symbolizes movement and flow, suggesting the upward progression of the stairs. It contributes to the overall aesthetic harmony and craftsmanship of the staircase, enhancing its visual impact.

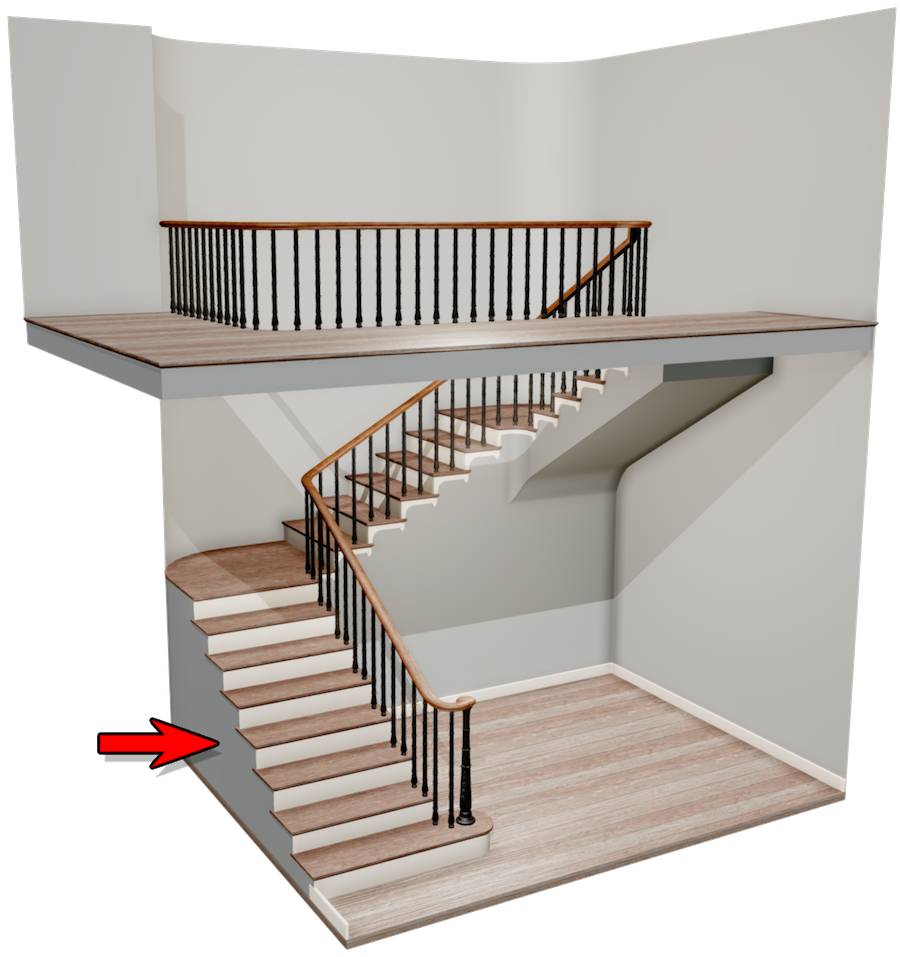

Atrium

An atrium, is an architectural feature or space within a building that is open to the sky, typically located at the center or near the entrance. It is a large, open area surrounded by multiple floors or wings of the building, often with a glazed or transparent roof that allows natural light to enter the space.

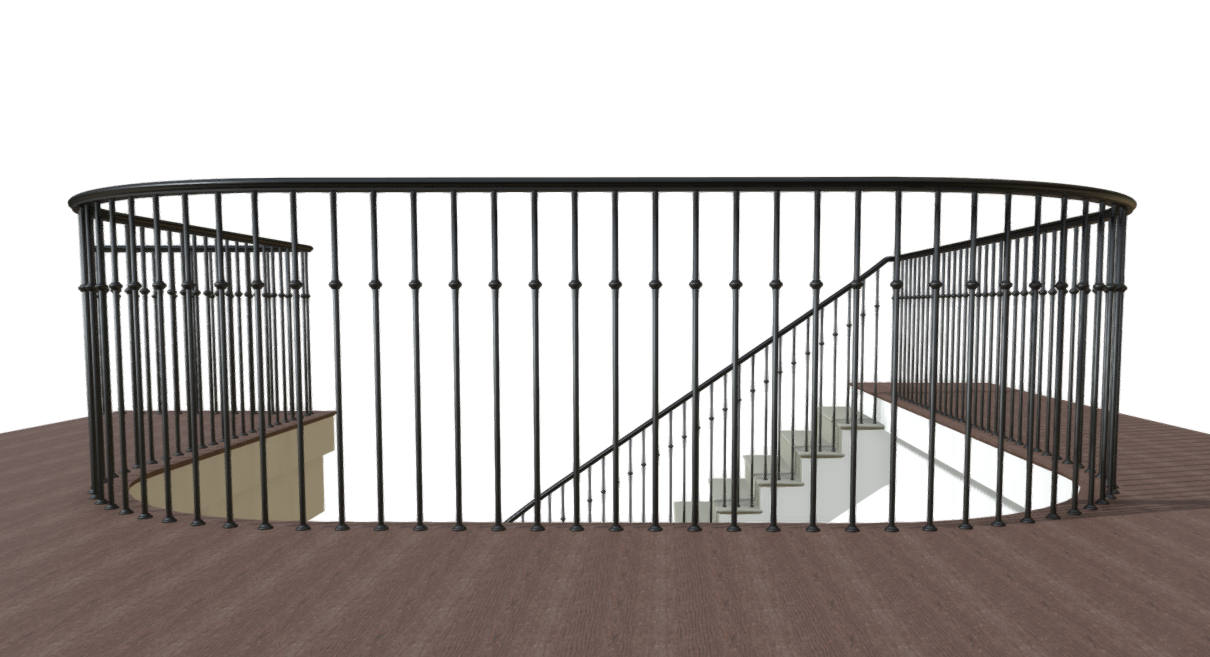

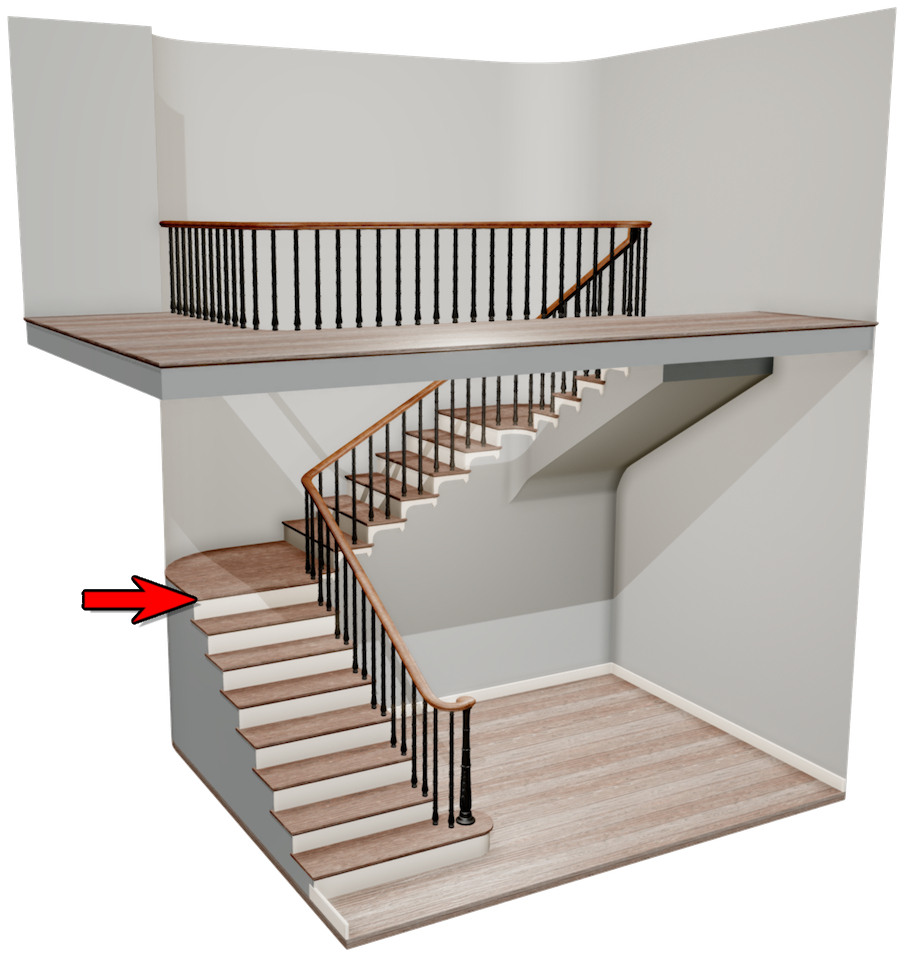

Having an atrium in the entrance of a home often means that landing balcony balustrading would be required – see opposite.

Awning

An awning is a secondary covering typically attached to the exterior wall of a building, over a window, door, or patio area. It consists of a lightweight frame structure covered with fabric or other materials. The primary purpose of an awning is to provide shade and protection from the sun, rain, or other elements, creating a sheltered space.

Awnings come in various styles and designs, ranging from fixed or stationary to retractable options that can be extended or folded back as needed. They serve both functional and aesthetic purposes, enhancing the energy efficiency of a building by reducing sunlight and heat penetration while also adding a decorative element to the exterior. Awnings are commonly used in residential and commercial settings, offering a practical solution for outdoor comfort and weather protection.

Occasionally our cantilever canopies have been used for a sun awning providing shade and protection over windows.

B

Back Stay – Back Stile – Baluster – Balustrade – Bannister – Baroque – Baserail – Bevel – Bezel – Billet – Birdsmouth – Bracket – Brass – Bronze – Bronzing – Bullnose Tread – Bun – Bun Volute – Burnishing – Burr

Back Stay

.A stay is generally used to provide rigidity to a longer run of railings or fencing, it serves as an angled bracing piece between the railing and the ground.

Back stile

This refers to the vertical bar of a gate frame, on which it hinges. It is usually a thicker, heavier bar as it needs to carry the weight and pivoting load of the gate

Baluster

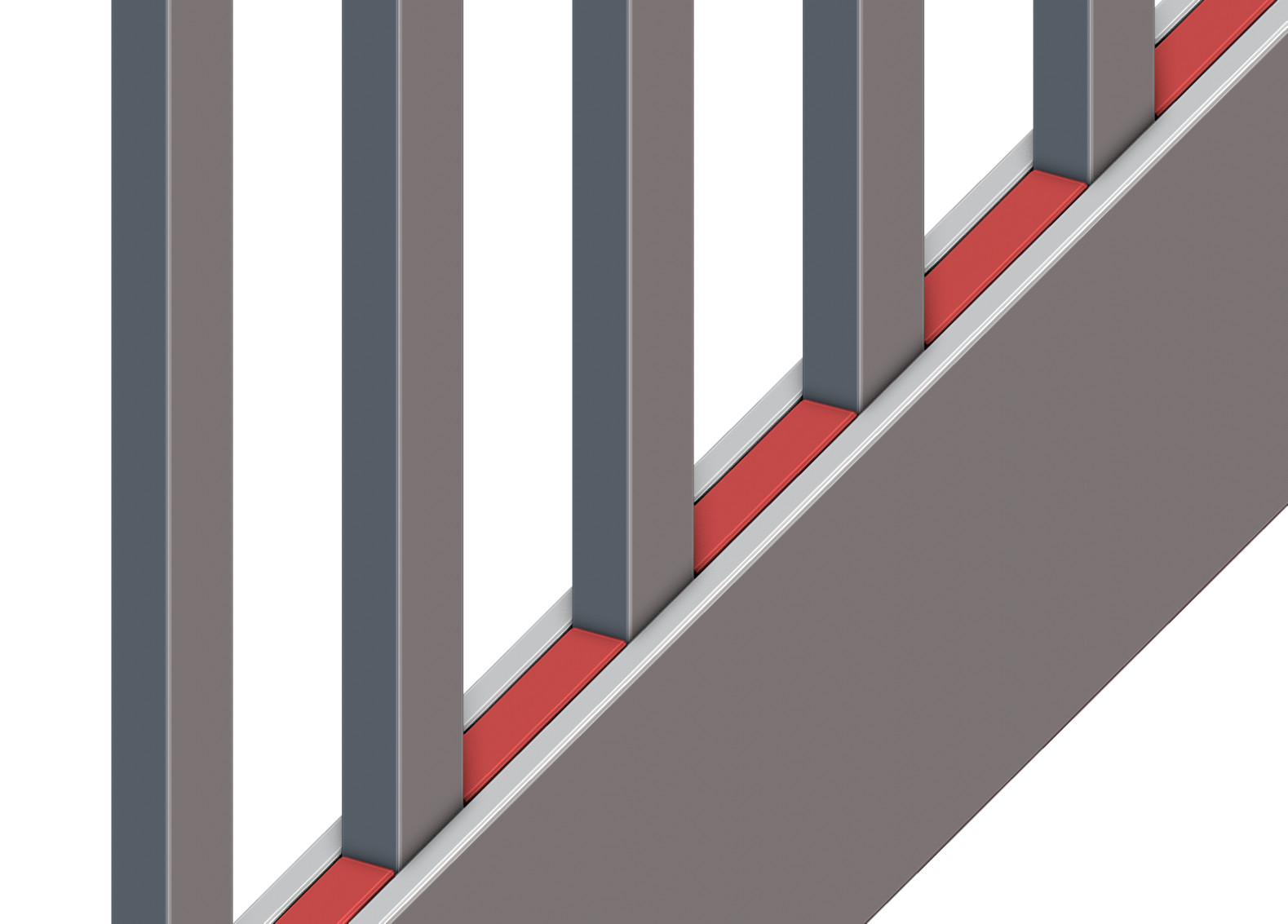

A baluster (sometimes called a spindle) is a vertical structural component that forms part of a balustrade, which is a railing system that provides support and safety along the edge of a staircase, balcony, or elevated platform. Balusters are typically evenly spaced and serve as vertical supports between the handrail and the lower rail, also known as the base rail.

Balusters can vary in terms of their spacing, design, and ornamentation. Some balusters may be plain and simple, while others may feature intricate carvings, patterns, or embellishments, reflecting the architectural style or personal taste of the space.

Balusters are typically attached to a corerail which fixes to the handrail and the baserail or the treads of the staircase. This ensures that they are properly aligned and provide adequate support and stability. Building codes and regulations often dictate specific requirements for baluster spacing, height, and strength to ensure the safety of staircases and guardrails.

Balustrade

A balustrade is a collective term for the baserail, balusters and corerail of a staircase.

In addition to their functional purpose of providing safety and stability, balustrades are an opportunity to showcase creativity and add visual interest to a staircase or balcony. From simple and streamlined designs to ornate and intricate details, the balustrade plays a significant role in the overall appeal and character of the space.

Compliance with building codes and regulations is important when designing and constructing a balustrade to ensure the proper height, spacing, and strength of the components for safe usage.

Bannister

(See Balustrade above)

A bannister, also known as a handrail or railing, is a structural and decorative component found in buildings, particularly on staircases and balconies. It serves as a safety feature by providing support and stability to individuals while ascending or descending stairs or standing on an elevated platform.

Typically made of wood, metal, or a combination of both, a bannister consists of several key elements including the baserail, corerail, balusters and handrail.

Baroque

Baroque is an elaborate style of art, architecture, and music rather than a historical period. This style emerged in Europe in the late 16th century and reached its peak during the 17th and early 18th centuries. It is characterized by its ornate, elaborate, and highly detailed aesthetics, as well as its dramatic and emotional qualities. Baroque art and culture were particularly prominent in countries such as Italy, Spain, France, and Germany during this period.

Baserail

The Baserail, also referred to as the lower or shoe rail, is a horizontal rail that runs parallel to the handrail at the bottom of the balustrade. It provides structural support and adds visual continuity to the balustrade system. In some designs, the lower rail may be absent, and the balusters may connect directly to the treads or the structural supports.

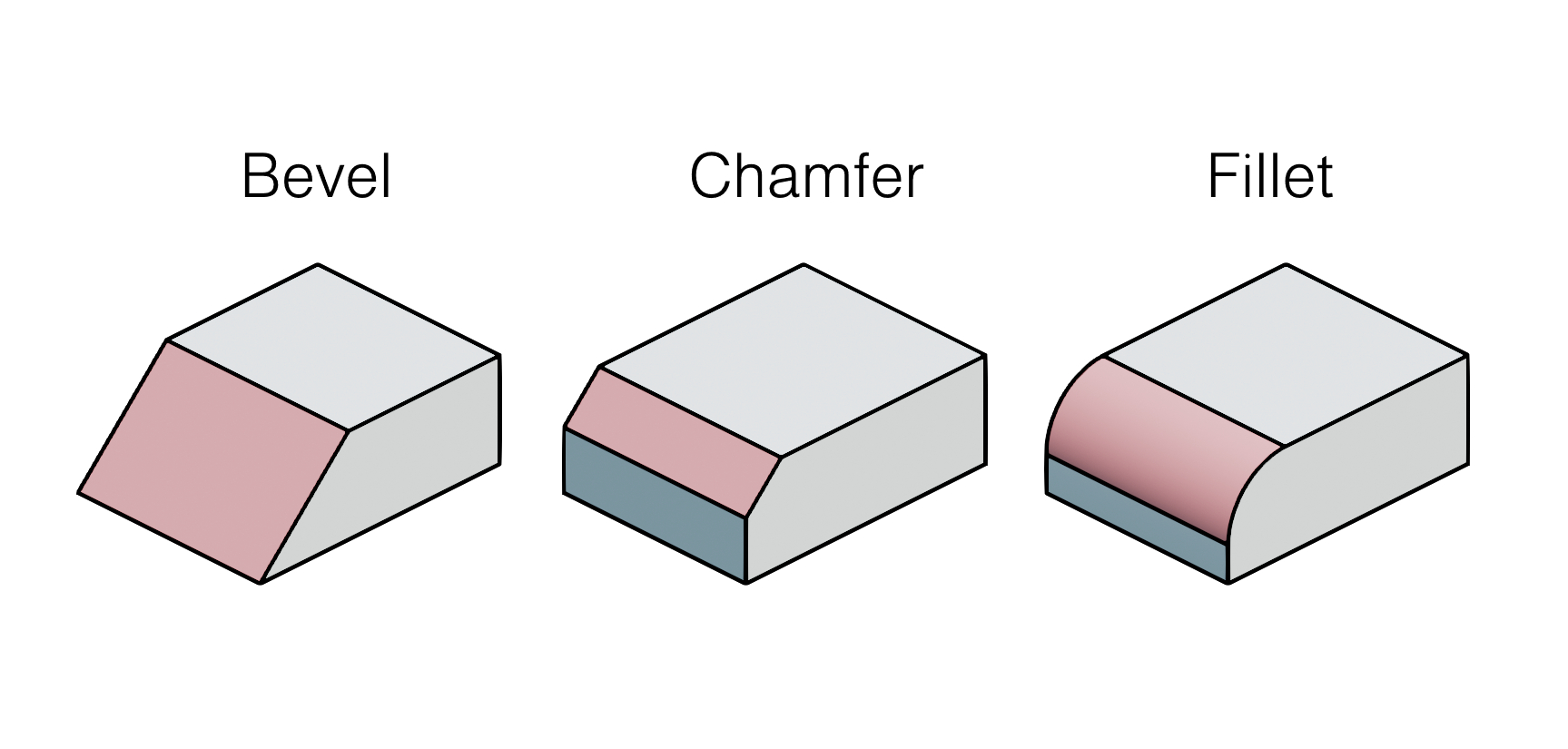

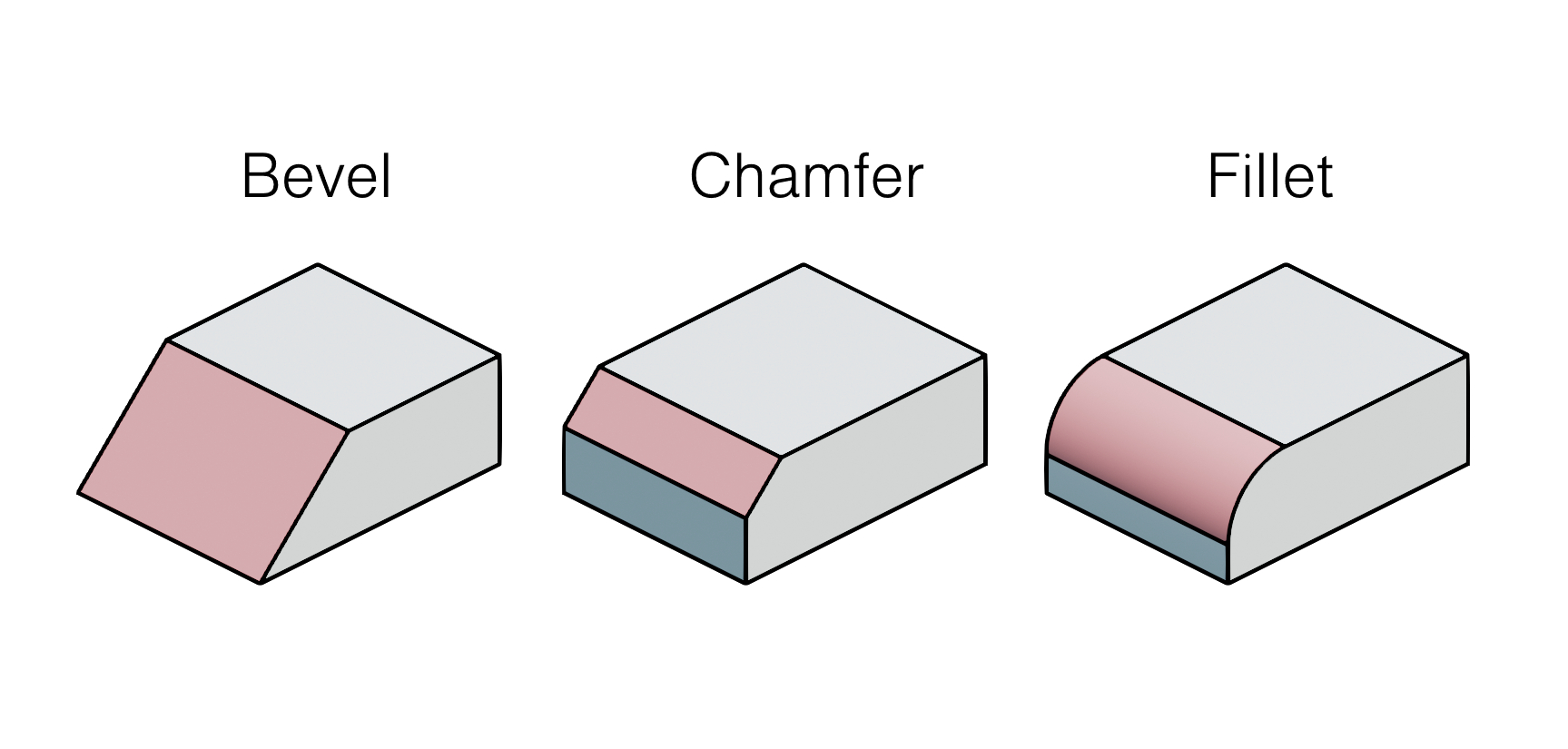

Bevel

A bevel is an angled face, often 45 degrees. Beveled edges can be decorative (refining a sharp right-angled edge) or serve functional purposes, such as making it easier to weld two pieces of metal together by providing a groove for the weld to penetrate.

Bezel

A bezel is a frame or rim designed to hold something in place, for example glass.

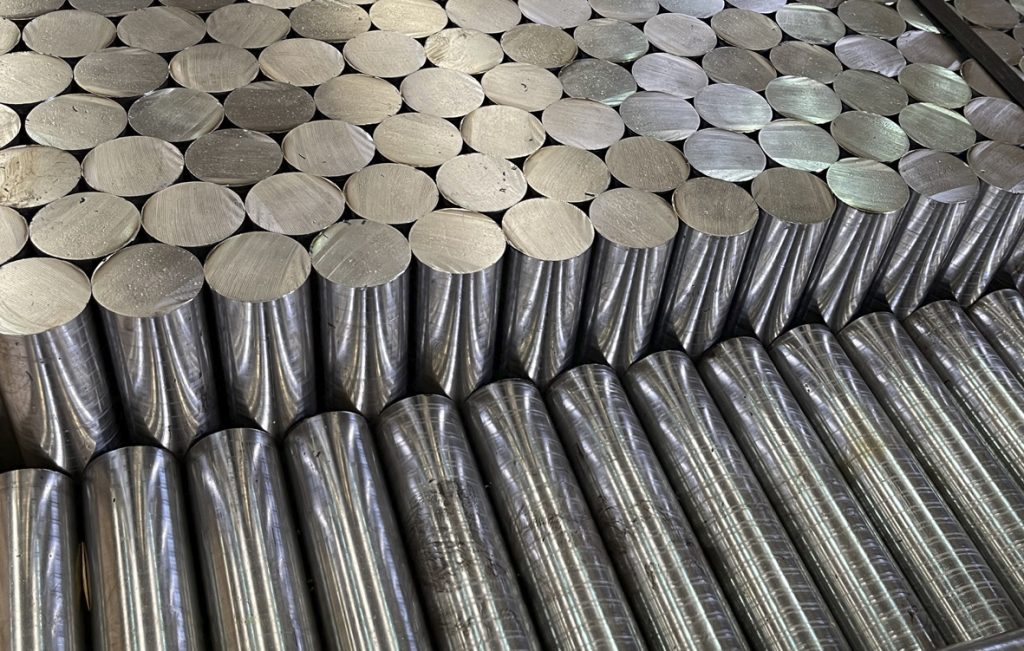

Billet

Also known as an ingot. This refers to the initial mass of metal prior to being processed to the desired size or section.

Birdsmouth

A birdsmouth is a specialized type of cut or notch made in a structural member, typically a wooden or metal beam, rafter, or truss. This cut is also sometimes referred to as a “bird’s beak”. The primary purpose of a birdsmouth cut is to allow the structural member to securely sit on top of another member, such as a wall plate or a supporting wall, ensuring proper load transfer and stability in roof and floor framing.

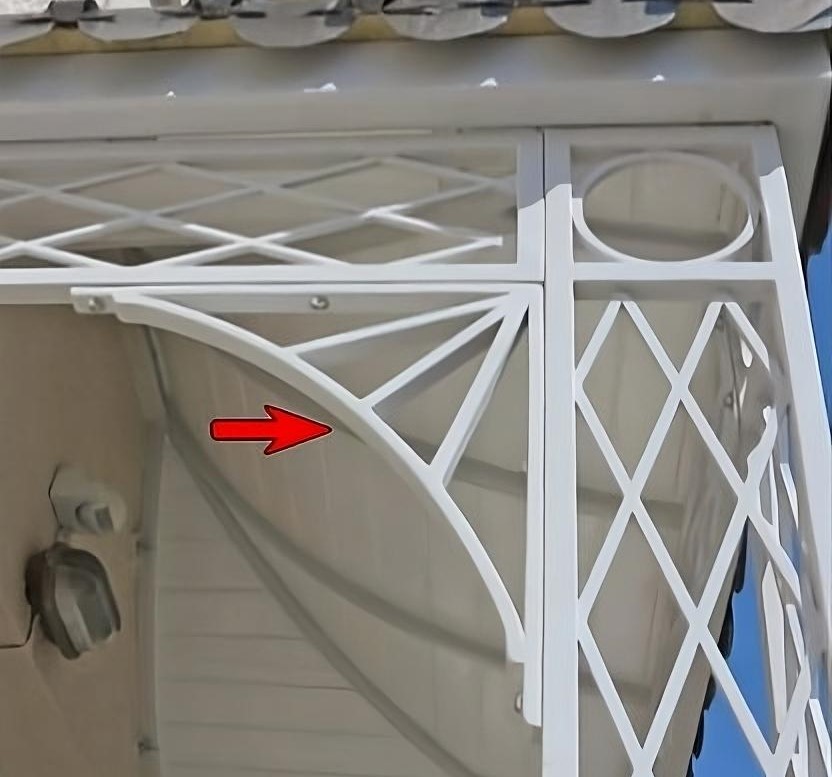

Bracket

(see also Spandrel) A bracket is a linking element between components and is generally used for additional support and/ or as a decorative element. They are used in a number of applications, though most commonly in Fine Iron they are known as Spandrels and are used to support our cantilever canopies or as additional support and decorative elements for Balconies, Porches and Verandas.

Brass

Brass is a metallic alloy composed primarily of copper and zinc. It is widely recognized for its distinctive yellowish-gold appearance, which can vary in shade depending on the specific composition of the alloy. Brass has been used for centuries and is valued for its unique combination of properties.

Brass is primarily made up of copper (usually ranging from 55% to 90%) and zinc (typically ranging from 10% to 45%). Small amounts of other elements, such as lead, tin, or aluminum, may also be added to achieve specific properties.

Brass exhibits a warm golden or yellowish color that can resemble gold. The shade of brass can vary depending on the exact proportions of copper and zinc and may be altered through surface treatments or coatings (see Patination).

Brass is a relatively strong and durable alloy, providing good resistance to deformation and wear. Its strength can be further enhanced by adjusting the composition and through various heat treatments. It also has excellent corrosion resistance, especially in atmospheric and marine environments. This property makes it suitable for applications exposed to moisture or harsh conditions, such as plumbing fittings or marine hardware.

Brass is highly machinable, meaning it can be easily shaped, cut, drilled, or milled using common machining techniques. Its relatively low melting point and good workability allow for precise and intricate manufacturing processes. This along with it’s appealing color and luster make it a popular choice for decorative items, sculptures, architectural accents such as handrailing and jewelry making.

Bright Steel

Is a type of carbon steel that has been processed to have a smooth, clean, and shiny surface finish. This finish is achieved through processes such as cold drawing, grinding, polishing, or peeling, which remove the scale, oxide layers, and other surface imperfections typically found in raw steel.

It is a popular material in various industries, including construction, manufacturing, and engineering, due to its versatility, strength, and ease of machining.

Bronze

Bronze is a castable metallic alloy, with modern bronze being primarily composed of around 89% copper and 11% tin although other elements such as aluminium, manganese or zinc may also be used.

There are in fact 9 types of bronze used today including:-

- Tin Bronze – As mentioned above this is composed of around 89% Copper and 11% Tin. This alloy has great mechanical qualities which makes it a good choice for gears, bearings and structural elements even though the cost of the metal is higher.

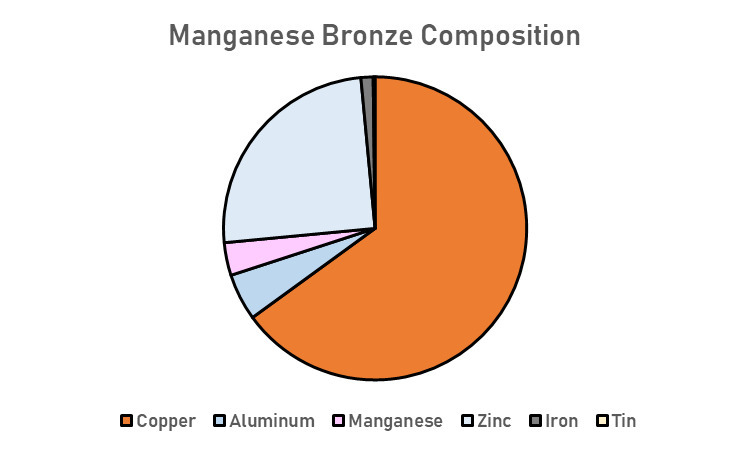

- Manganese Bronze – Made up of around 60-68% Copper, 25% Zinc, 3-7.5% Aluminium, 2-4% Iron and 2.5-5% Manganese, this Bronze alloy exhibits excellent strength and wear resistance and whilst these qualities make it more challenging to machine it has an impressive tensile strength and fatigue resistance.

- Copper-Nickel Bronze – Contains 90% Copper and 2-30% Nickel and is a popular alloy due to its corrosion resistance, longevity and excellent thermal stability.

- Bearing Bronze – Composed of 81-85% Copper, 6-8% lead, 6.3-7.5% Tin and 2-4% Zinc among other trace elements. Often used for light-duty applications due to its malleability.

- Bismuth Bronze – Sometimes referred to as lead free Bronze. It usually contains 87-91% Copper, 1-6% Bismuth, 1% Nickel and 2-4% Tin and Zinc and is commonly used in plumbing and other applications where water is required to be safe for drinking.

- Nickel Aluminium Bronze – Typically composed of 79% Copper, 8.5-9.5% Aluminium and 3.5-4.5% Nickel, this Bronze is particularly strong due to the addition of Iron and Nickel making it perfect for bearings, wear plates and bushings.

- Silicon Bronze – Contains 94-96% Copper, 2.5-6% Silicon and 0.3-1.4% iron as well as trace amounts of manganese. It is commonly used in welding rods, marine hardware and architectural embellishments.

- Phosphor Bronze – Containing around 95% Copper, 0.5- 11% Tin, and 0.01-0.35% Phosphorus, it’s more fluid in it’s molten state which aids casting and is widely used for springs, bolts and electrical contacts.

- Aluminium Bronze – Typically 9-14% Aluminium, 4% iron and about 82% Copper. This is the most widely used bronze alloy owing to it’s strength, durability and corrosion resistance.

Bronze’s exceptional combination of strength, durability, corrosion resistance, and machinability has led to its use in numerous applications, including architectural accents, sculptures, musical instruments, coinage, marine components, bearings, electrical connectors, and more. Its timeless appeal, reliability, and enduring legacy contribute to the continued appreciation and utilization of bronze in various fields.

It is an ancient alloy that has been utilized for thousands of years with the first Bronze artifacts being made around 4500BCE, though bronze artifacts didn’t become more commonplace until around 3300BCE – The Bronze Age. Proportions of copper to tin varied greatly until about the middle ages in Europe when bronze making was refined and certain proportions were known to have specific properties.

Until the Middle Ages, bronze was crafted through the lost-wax method, also known as cire perdue. This technique involved molds that could only be used once, making it the most exclusive method due to its cost and its ability to produce exquisite work aesthetically. Subsequently, casting evolved to utilize models composed of multiple detachable pieces, typically crafted from wood. These models could be pressed into sand molds, resulting in the emergence of the object’s shape as a hollow. Molten bronze was then poured into these molds through casting ducts. After the piece was extracted from the sand mold, its surface was smoothed and casting seams were eliminated. The wooden model could then be reused to produce as many copies as needed, enabling economical production.

Bronzing

Bronzing is the process of giving an object or surface the appearance of being made of bronze. It involves applying a bronze-like finish or patina to achieve the desired effect. There are different methods for bronzing:

One method involves using spray paint or paint with metallic bronze pigments to coat the object’s surface. This provides a quick and cost-effective way to create a bronze-like appearance.

Another method is powder coating, where powdered bronze or bronze-colored pigments are electrostatically applied to the surface and then heated to form a durable coating.

Chemical patination is a technique that involves using chemicals or patina solutions to create a layer on the object’s surface that mimics the aged or oxidized look of bronze. This method is often used to achieve a natural-looking bronze patina.

Metal plating, such as bronze plating, electroplates a layer of bronze onto the object’s surface, creating an authentic bronze finish.

Bronzing can be applied to various materials such as wood, ceramics, plastic, and metal to achieve the desired bronze-like appearance. It is commonly used in decorative arts, sculptures, furniture, architectural accents, and other objects where the look of bronze is desired without using actual bronze.

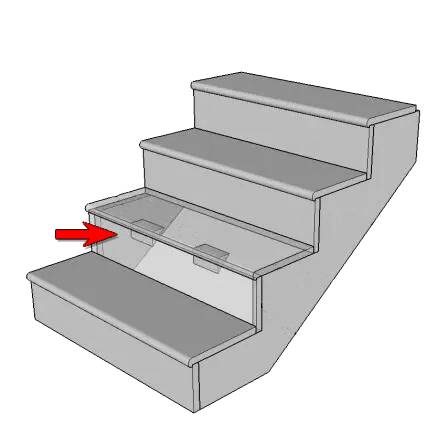

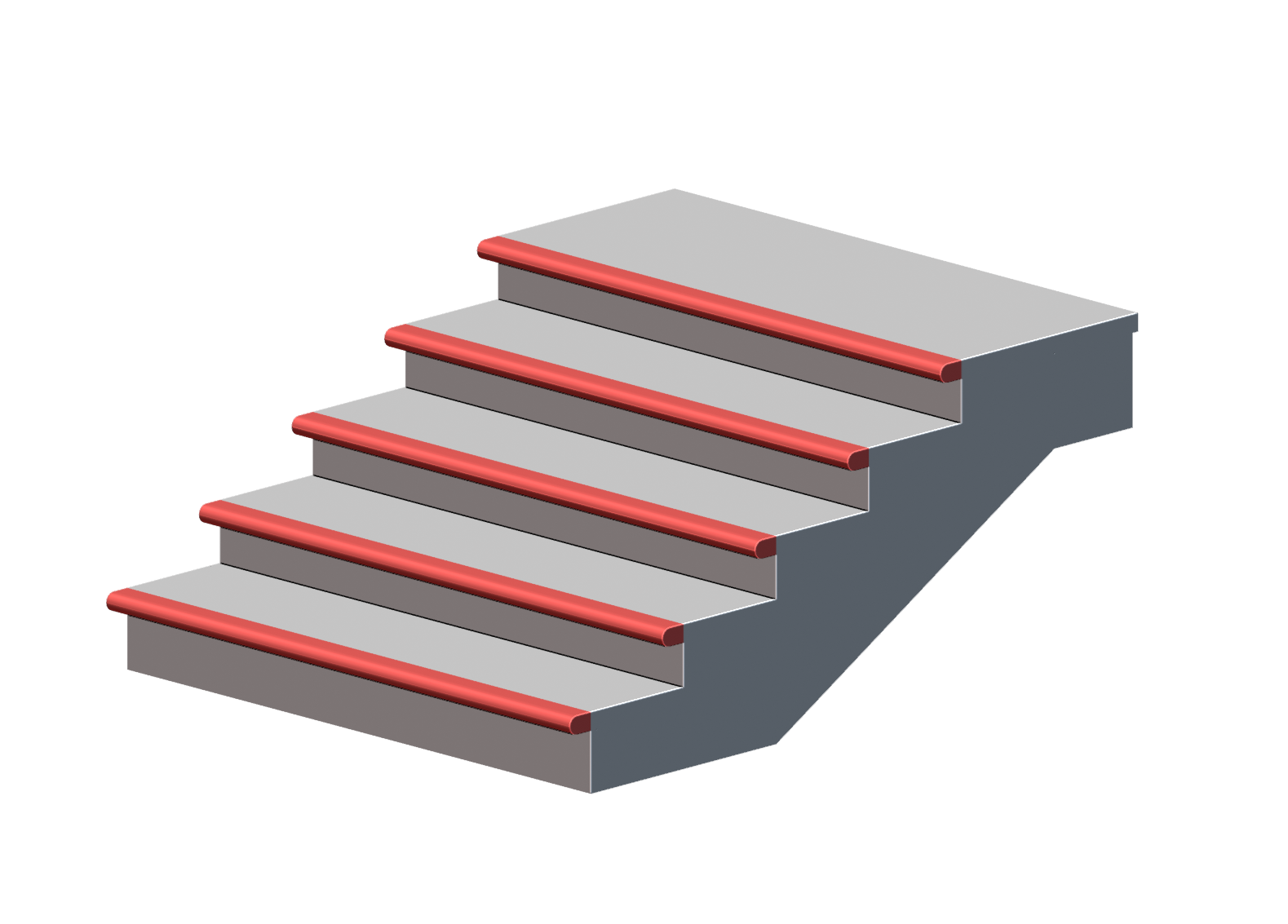

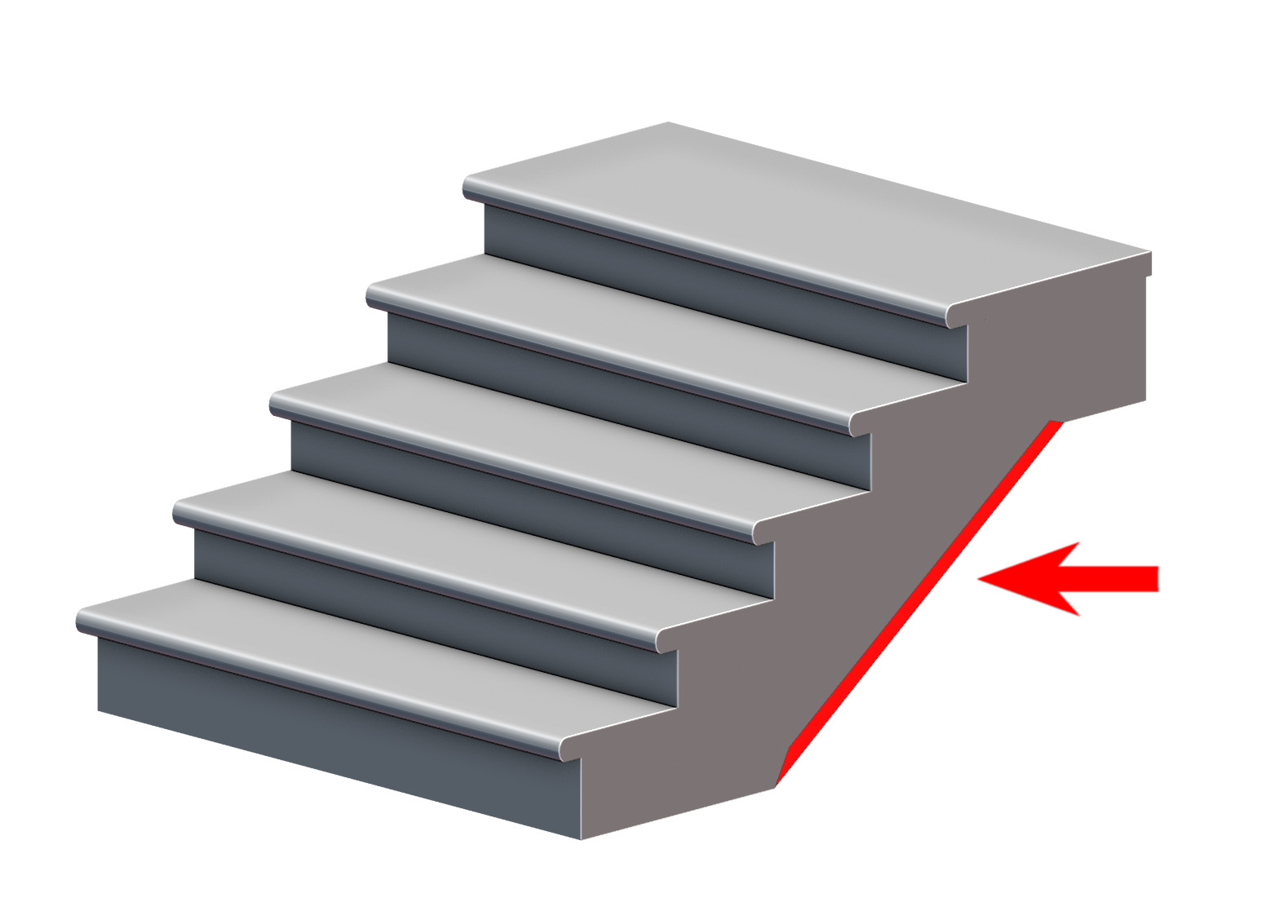

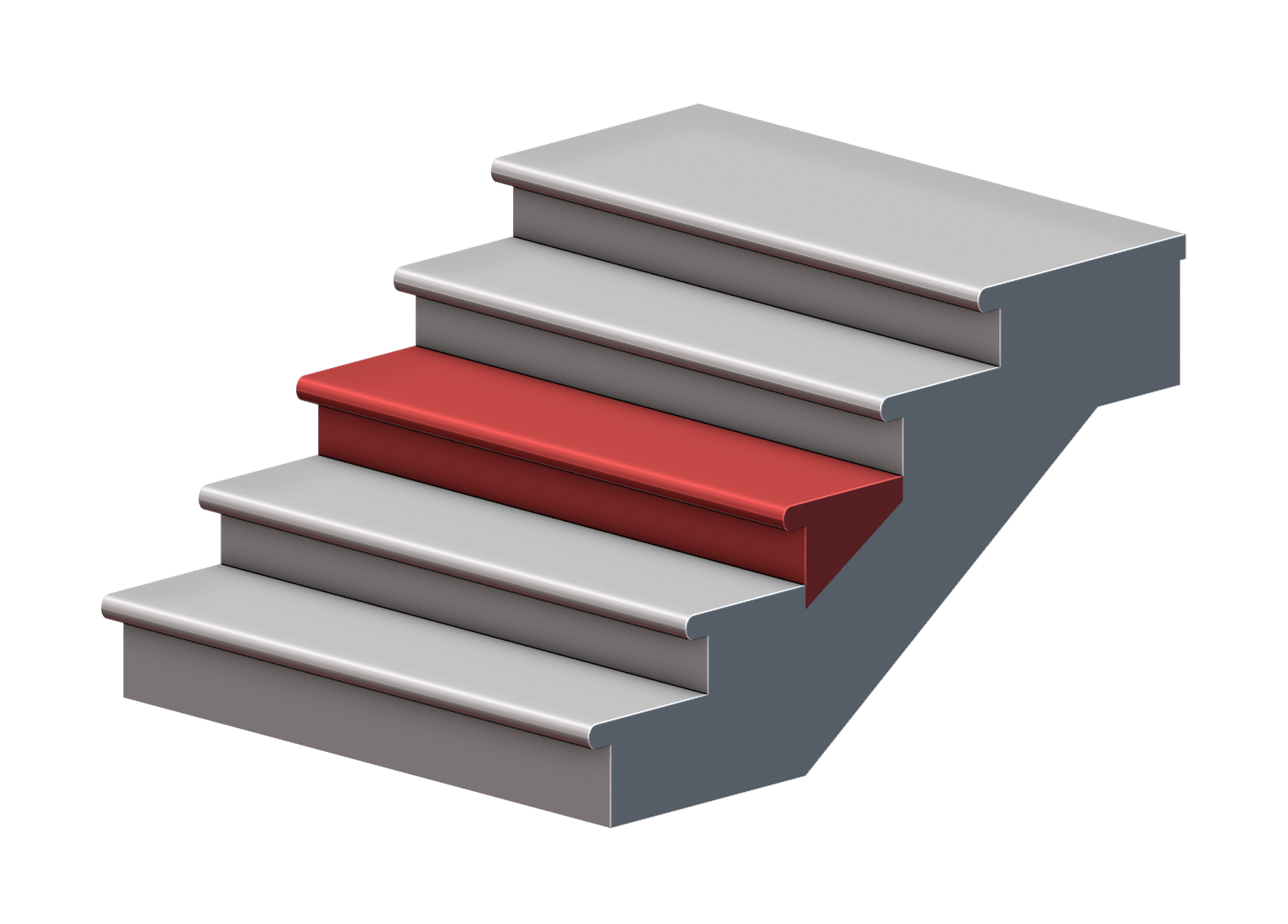

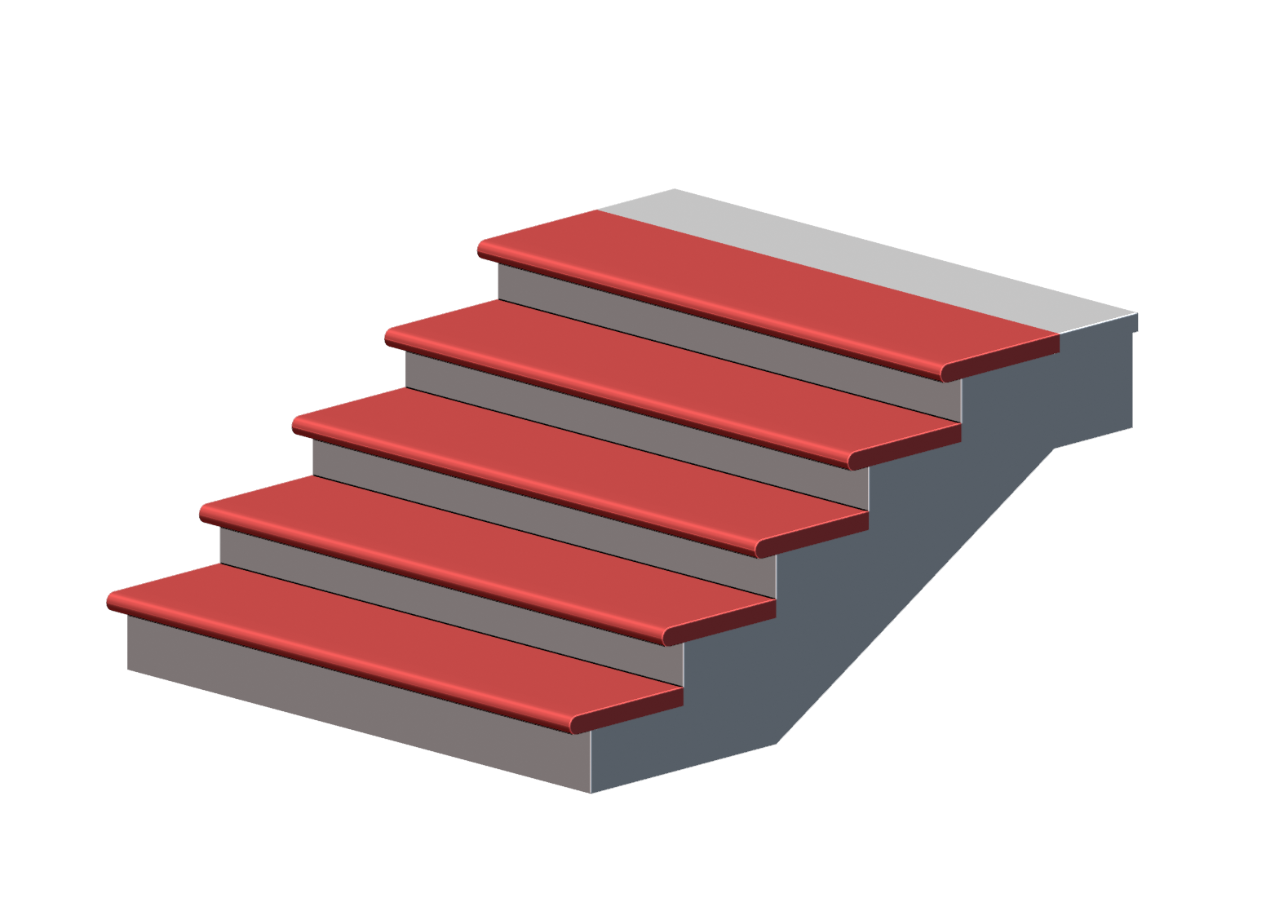

Bullnose Tread

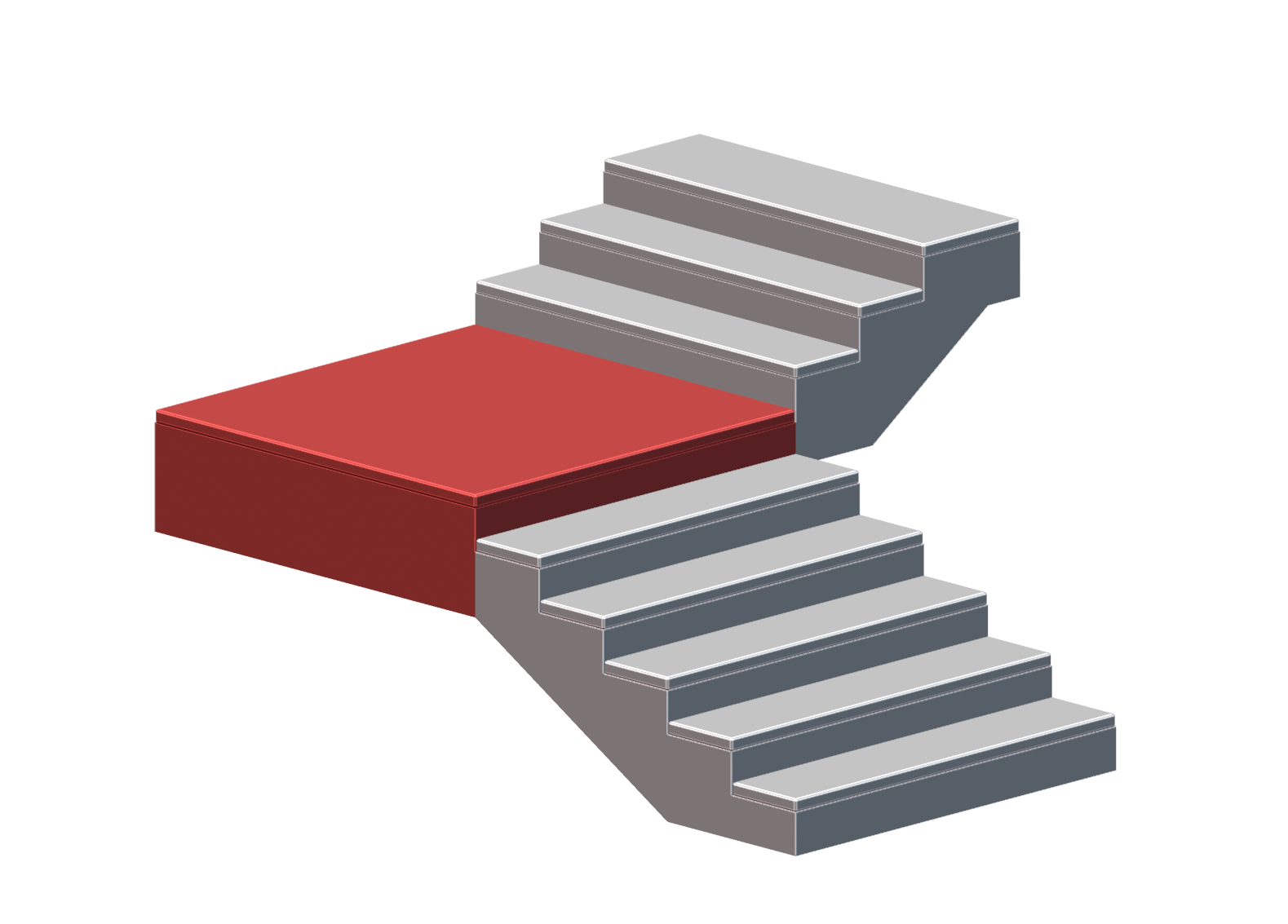

A bullnose tread is used for the first or feature treads and describes a simple, quater circle end to either one or both sides of the tread.

This shape can be used for staircases where a D tread would not fit or is sometimes used for the second step often with a D tread to the first step as shown opposite.

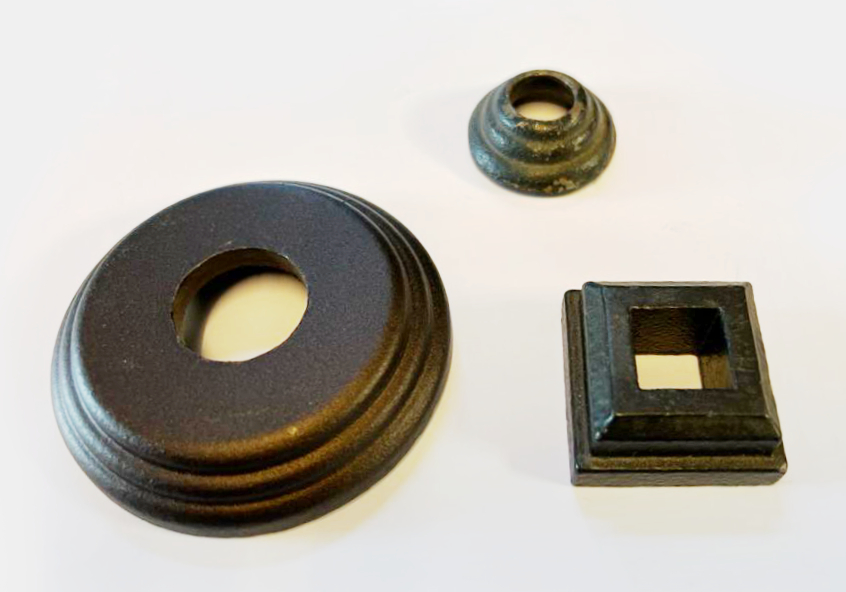

Bun

This describes a round opening cap used to terminate a handrail at the Newel post.

Opening cap’s are usually round but can be square or even octagonal in shape.

Burnishing

Burnishing refers to a finishing process used to create a smooth, shiny, and polished surface on metal. It involves applying pressure and friction to the surface using a specialized tool or abrasive material.

The burnishing process involves rubbing or polishing the material with a smooth, hard object such as a burnishing tool, a polished stone, or a burnishing bone. The tool is pressed firmly against the surface and moved in a back-and-forth or circular motion. The friction generated by the pressure and movement causes the surface layers of the material to deform and become denser, resulting in a polished and reflective appearance.

The main objective of burnishing is to smoothen out any imperfections, irregularities, or roughness on the surface. It can also be used to enhance the material’s luster and bring out its natural shine. Burnishing is often employed in metalworking to refine the finish of metal objects or jewelry, creating a glossy and reflective surface.

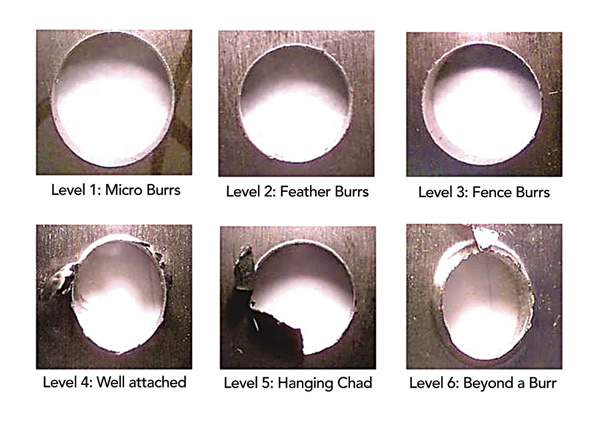

Burr

Is a rough or sharp edge left after filing, cutting or drilling metal. Fine Iron de-burr all of our ironwork.

C

Canopy

An ironwork door canopy is a decorative and functional architectural element typically installed above an entrance, such as a door or porch. It is a cantilever structure, meaning that it is supported with spandrels (sometimes called brackets) rather than having ironwork going to ground making it the perfect solution for an area with limited space or where clear acess is required. Our canopies are designed to provide shelter from the elements while enhancing the visual appeal of a building.

We have a broad range of canopy styles which feature various ironwork designs, including scrollwork, floral motifs, cast iron details or more contemporary styles. Ironwork door canopies are not only durable and weather-resistant but also add a touch of elegance to the exterior of a structure, making them a popular choice in architectural design.

Carbon Steel

Carbon steel is a versatile and widely used category of steel alloys primarily composed of iron and carbon. It is known for its strength, durability, and affordability. The carbon content in carbon steel typically ranges from 0.05% to 2.0%, making it less prone to corrosion than some other types of steel. It can be easily welded, machined, and formed into various shapes, which makes it suitable for a wide range of applications, including construction, automotive, manufacturing, and structural engineering. The properties and characteristics of carbon steel can vary depending on the carbon content and other alloying elements, but it is a foundational material in many industries due to its reliability and cost-effectiveness.

Carriage

The carriage of a staircase is responsible for bearing the weight and transferring the loads imposed by individuals using the staircase. It is crucial to ensure that the carriage is properly designed, constructed, and supported to maintain the structural integrity and safety of the staircase.

Different types of staircases may have variations in their carriage design, such as open-stringer or closed-stringer configurations, depending on the architectural style and construction requirements. Additionally, materials used for the carriage can vary, including wood, steel, concrete, or a combination of these materials.

Cartouche

A cartouche is a decorative or ornamental element typically made of metal and shaped like an elongated oval or rectangle. It is often used to frame or encase an inscription, coat of arms, or other decorative motifs. Cartouches in metalwork can be crafted from a variety of metals, such as brass, bronze, or even precious metals like gold or silver, depending on the intended purpose and aesthetic.

These metal cartouches are frequently found on various items, including furniture, jewelry, plaques, and architectural features. They serve both a functional and decorative purpose, adding an element of elegance and sophistication to the object or structure they adorn. The design and style of metal cartouches can vary widely, from intricate and ornate patterns to simpler, more contemporary designs, making them a versatile and aesthetically pleasing component in metal craftsmanship

Cast Iron

Cast iron is a strong, versatile, and durable material that is commonly used in a wide range of applications, including cookware, balustrades, gates and railings and more. It is a type of iron-carbon alloy that contains a higher proportion of carbon than steel, typically ranging from 2% to 4% carbon content. This higher carbon content gives cast iron its distinctive properties, including its brittleness, excellent heat retention, and good machinability.

Cast iron’s high carbon content makes it susceptible to brittleness, which can lead to cracking under certain conditions. However, its benefits, such as excellent heat retention and ease of casting, outweigh its limitations in many applications. Despite its historical use, modern engineering and manufacturing techniques have enabled the development of cast iron alloys with improved properties and greater suitability for specific applications.

Centreline

The flow of the handrail, spindle positions, and stringer faces is controlled by the center line, making it a crucial aspect of staircase design.

To determine the center line, start from the center of the handrail and extend it downwards through the chosen support structure, whether it’s a spindle, glass panel, or baluster, until it reaches the staircase. This process enables you to calculate the outer edge of the staircase.

Chamfer

A chamfer is a beveled edge or surface, typically created by removing material from a right-angled corner or edge of an object. It serves practical, safety, and aesthetic purposes in various applications, and the angle and size of the chamfer can be tailored to the specific requirements of the project.

A chamfer is usually a flat, non-rounded edge that forms an angle, most commonly 45 degrees or 90 degrees. It can be created by machining processes like milling, grinding, or hand tools like chisels or files.

Chamfers are applied for several reasons including:-

-

- Safety: Chamfering sharp edges reduces the risk of injury, as it eliminates sharp corners that can be hazardous in some applications.

- Aesthetics: Chamfers can improve the visual appearance of an object by providing a more finished and polished look.

- Ease of Assembly: Chamfers can help parts fit together more smoothly, especially in mechanical or woodworking applications, where they can aid in alignment and reduce the risk of splintering.

- Stress Relief: Chamfers can reduce stress concentrations at corners or edges, which can be beneficial in structural or engineering design.

There are different types of chamfers, including:

- External Chamfer: Applied to the outer edges or corners of a workpiece.

- Internal Chamfer: Applied to the inner edges or corners of a hole or cutout.

- Tapered Chamfer: Gradually tapers from one edge to another, rather than having a uniform angle.

Channel

In metalwork and structural engineering, a channel section, also known as a C-channel or simply a channel, is a type of rolled steel or metal shape characterized by its “C” or “U” cross-sectional profile. It is a widely used structural component known for its versatility and strength. Channel sections are commonly used in construction, manufacturing, and various industrial applications.

Channel sections are widely used as structural components in buildings, bridges, and various infrastructure projects. They serve as beams, columns, and support members, providing structural stability and load-bearing capabilities. Channel is available in various sizes and configurations to accommodate different applications. The flange sizes and thicknesses can be customized to meet specific project requirements

CHS

Stands for Circular Hollow Section, also known as a round hollow section or simply a circular tube, is a type of structural steel or metal tubing characterized by its circular cross-sectional shape. CHS is commonly used in various construction and engineering applications due to its structural strength, versatility, and aesthetic appeal.

CHS is widely used in construction and structural engineering for a variety of applications, including as columns, beams, braces, and support elements in buildings, bridges, and infrastructure projects. Its circular shape distributes loads evenly, enhancing structural stability.

Circular Staircase

A circular staircase follow a circle with a singular centre of curvature and a large radius. This differs from a spiral staircase which is built around a central post and often used for areas with limited space.

A circular staircase is a traditional and elegant style, though the shape lends itself beautifully to more contemporary balustrading.

Closed String

A closed stringer is a type of stair stringer commonly used in staircase construction. Unlike a cut stringer where the edges of the treads and risers are exposed, a closed stringer is designed to enclose the steps, concealing the edges and providing a more traditional or solid appearance to the staircase.

One advantage of closed stringers is that they provide additional structural stability to the staircase, as the stringer itself adds strength and rigidity to the steps. This can be particularly important for wider or more heavily trafficked staircases.

Additionally, closed stringers offer the advantage of hiding the structural components of the staircase, such as the tread supports and riser attachments. This can create a cleaner and more finished appearance, especially when the staircase is located in a more formal or traditional setting.

Collar

(See also Boss and Base collar) A decorative element which can be found at the top, middle or base of a stair spindle.

Column

A metal column, also known as a metal pillar or post, is a structural element that provides vertical support in buildings and structures. These columns are typically made of metal, such as cast iron, mild steel or aluminum, due to their strength, durability, and load-bearing capacity. Metal columns play a crucial role in supporting the weight of a structure and transferring it to the foundation.

Metal columns come in various designs, shapes and sizes, ranging from simple forms to more elaborate styles which can feature fluted shafts and/ or decorative head and base details. They are used in both interior and exterior applications and can be found in a variety of architectural styles. In addition to their structural function, metal columns may serve aesthetic purposes, contributing to the overall design and visual appeal of a building.

These columns are commonly used in construction due to their ability to withstand heavy loads and provide reliable support over time. The choice of metal for columns is often driven by factors such as the required load-bearing capacity, the architectural design, and considerations for durability and resistance to environmental factors.

At Fine Iron we have a broad range of columns and decorative heads and bases which are most commonly used for porches, verandas and balconies.

Commode

This term relates to the shape of the feature or first tread of a staircase. Commode describes a curved or convex shape to the riser of the first tread and can be used with various shaped ends, for example you may wish to have a Commode tread with Curtail shaped ends

Conservation

Metalwork conservation is a specialized field that focuses on the preservation and restoration of metal objects and structures to prevent deterioration, maintain historical integrity, and extend their lifespan. It involves the careful examination, cleaning, repair, and protection of metal artifacts, sculptures, architectural features, and more. Conservation professionals employ various techniques and methods, such as cleaning, rust removal, corrosion prevention, and sometimes replication of missing or damaged parts, to ensure the longevity and visual quality of metal objects. The goal of metalwork conservation is to safeguard cultural heritage, maintain functional integrity, and protect the aesthetic value of these items for future generations.

Continuous Handrail

A continuous handrail is a type of handrail system that provides uninterrupted support and guidance along a staircase or walkway. It is characterized by a single, unbroken rail that spans the entire length of the staircase without any breaks or interruptions.

One of the main advantages of a continuous handrail is its seamless and flowing design. Unlike handrails with breaks or newel posts at intervals, the continuous handrail offers a sleek and continuous appearance that adds to the aesthetic appeal of the staircase. This design choice is often preferred in modern and contemporary architectural styles.

Continuous handrails are commonly made from various materials, including wood, metal, glass, or a combination of materials. The choice of material depends on factors such as the design preferences, durability requirements, and compatibility with the overall interior or exterior design scheme.

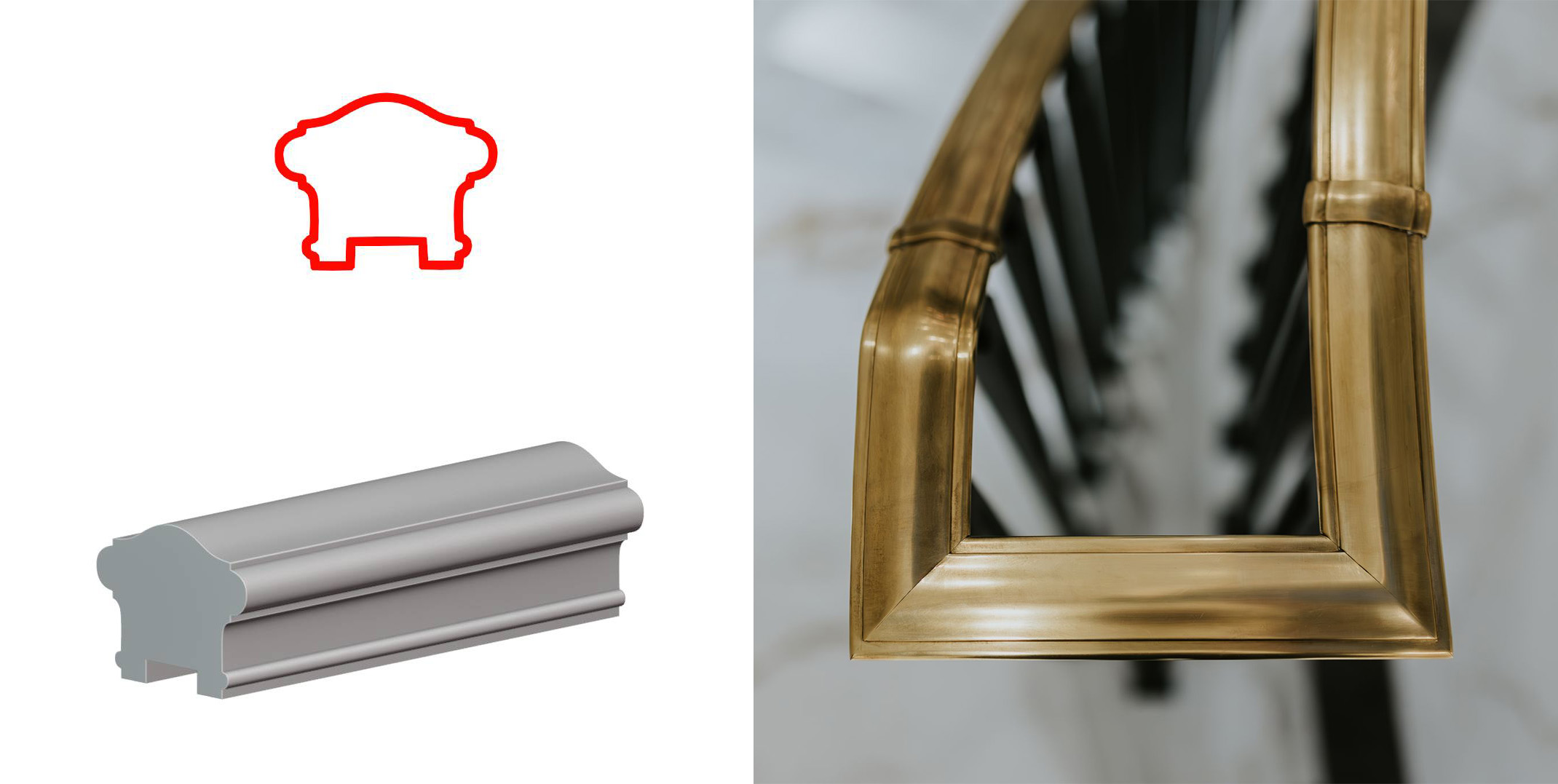

Convex Handrail

A convex handrail profile refers to a type of handrail design that features a gently curved shape that bulges outward. It is characterized by a smooth and rounded surface which allows the handrail to fit naturally within the palm of the hand, offering a secure and ergonomic grip while ascending or descending stairs.

Convex handrail profiles are commonly found in various architectural styles and are often utilized in both residential and commercial settings. The curvature can vary in terms of its degree of convexity, depending on the specific design preferences and functional requirements of the staircase.

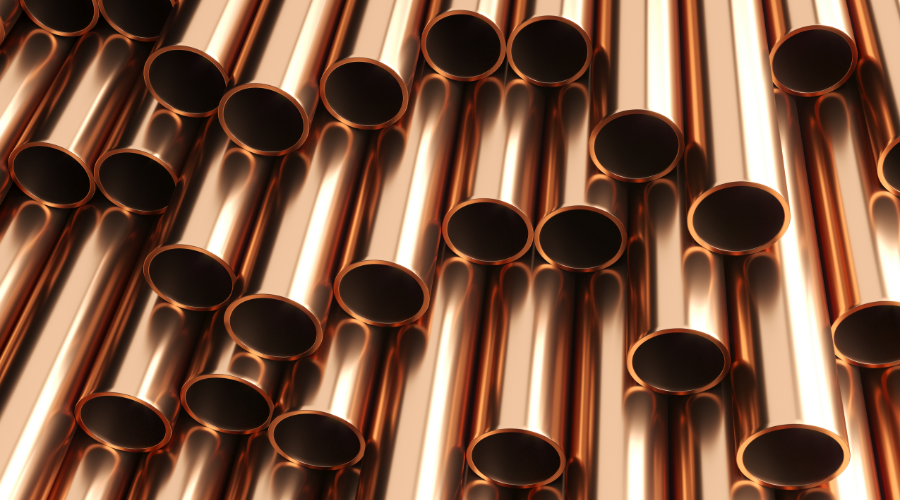

Copper

Copper is a chemical element with the symbol Cu and atomic number 29. It is a reddish-brown metal known for its excellent electrical conductivity, heat conductivity, and malleability. Copper has been used by humans for thousands of years, primarily for making tools, coins, and electrical wires. It is a crucial element in various industries, including construction, electronics, and plumbing, due to its corrosion resistance and versatility.

Copper’s distinctive color and malleability make it a popular choice in ornamental metalwork. Artisans and metalworkers use it for creating sculptures, wall art, and architectural features that add aesthetic appeal to buildings and interiors. Copper is also a popular choice for roofing and cladding , chosen for it’s longevity and attractive patina. Over time, the copper develops a unique greenish hue, which adds character to historic and contemporary buildings.

Corrosion

This is a natural process of deterioration and degradation that occurs when metals react with their environment, typically through chemical or electrochemical reactions. It often results in the breakdown of the metal and can lead to structural and aesthetic damage.

Corrosion is primarily triggered by exposure to environmental factors, such as moisture, oxygen, and pollutants, as well as the specific properties of the metal. Common forms of corrosion include rusting in iron and steel, tarnishing in copper and silver, and pitting in aluminum. There are various types of corrosion, including uniform corrosion (affecting the entire surface), localized corrosion (occurring in specific areas), and galvanic corrosion (resulting from the interaction of two dissimilar metals in an electrolyte).

Corrosion can weaken metal structures, reduce their lifespan, and impact their functionality. In addition to structural damage, it can lead to aesthetic issues, reducing the visual appeal of metalwork. Preventing and mitigating corrosion is essential. This can be achieved through measures such as applying protective coatings (e.g., paint, zinc thermal coating, galvanizing), using corrosion-resistant alloys, and implementing cathodic protection systems.

In metalworking and various industries, understanding and managing corrosion is crucial to ensure the longevity and performance of metal components and structures. Various methods and materials are employed to combat corrosion and extend the life of metal objects and infrastructure.

Curtail Ends

This term relates to the shape of the ends of the feature or first tread of a staircase. Curtail ends are reminiscent to a Roman Scroll shape and can often be seen on large sweeping staircases. They provide a more opulent or luxurious feel to the feature tread. This tread usually accommodates the newel post.

Cut String

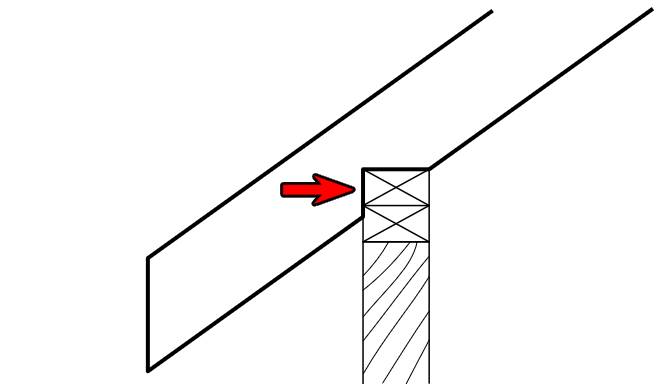

A Cut String refers to a type of stair stringer, which is a structural component that supports the treads and risers of a staircase. A cut string, also known as a “cut stringer,” is a particular style of stringer that has the profile of the steps cut out of it, exposing the edges of the treads and risers.

Cut strings are often used in contemporary or minimalist designs where the aesthetic appeal of the staircase is emphasized. They can be made from a variety of materials, including timber, metal, or even glass, depending on the design preferences and structural requirements.

D

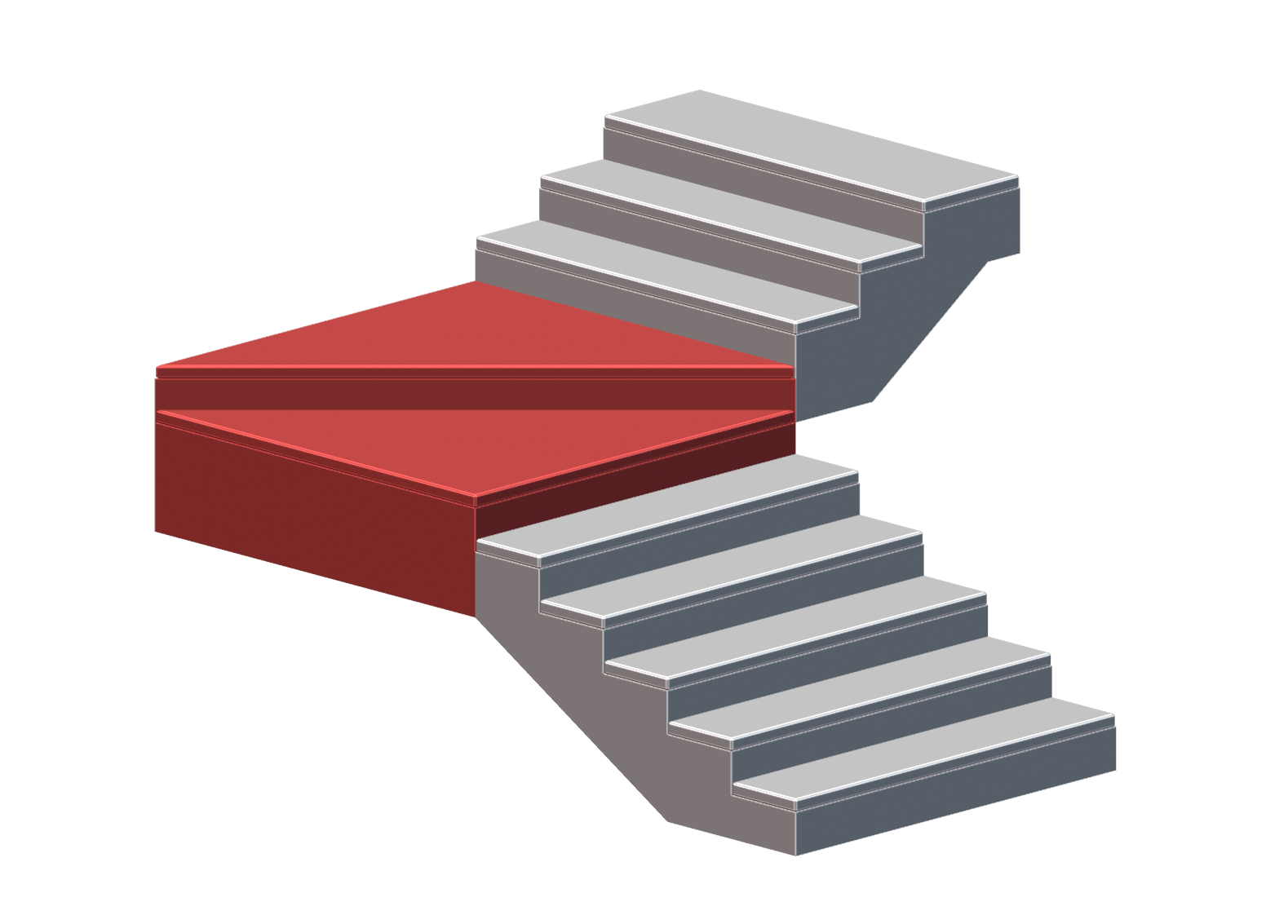

Dog Leg Staircase

A dog leg staircase, also known as a half-turn staircase or a U-shaped staircase, is a type of staircase design that changes direction by 180 degrees midway through its ascent. It consists of two flights of stairs that are connected by a landing or a platform, forming a U-shape or L-shape configuration when viewed from above.

Dog leg staircases are considered space-efficient as they occupy a relatively small footprint compared to other types of staircases. The 180-degree turn allows for a change in direction without requiring additional floor space. This makes dog leg staircases suitable for compact or limited space environments.

Drum

A drum is a radiused section of stringer, used to change direction and pitch through a tight turn. A drum is usually set either in the landing area between two flights or in the centre of the turn for a set of winder treads.

This will be used rather than a newel post at the change of direction when a geometric handrail is required.

D Tread

More rounded than a bullnose step, a D tread is used for the first tread and passes the newel post returning to the side

E

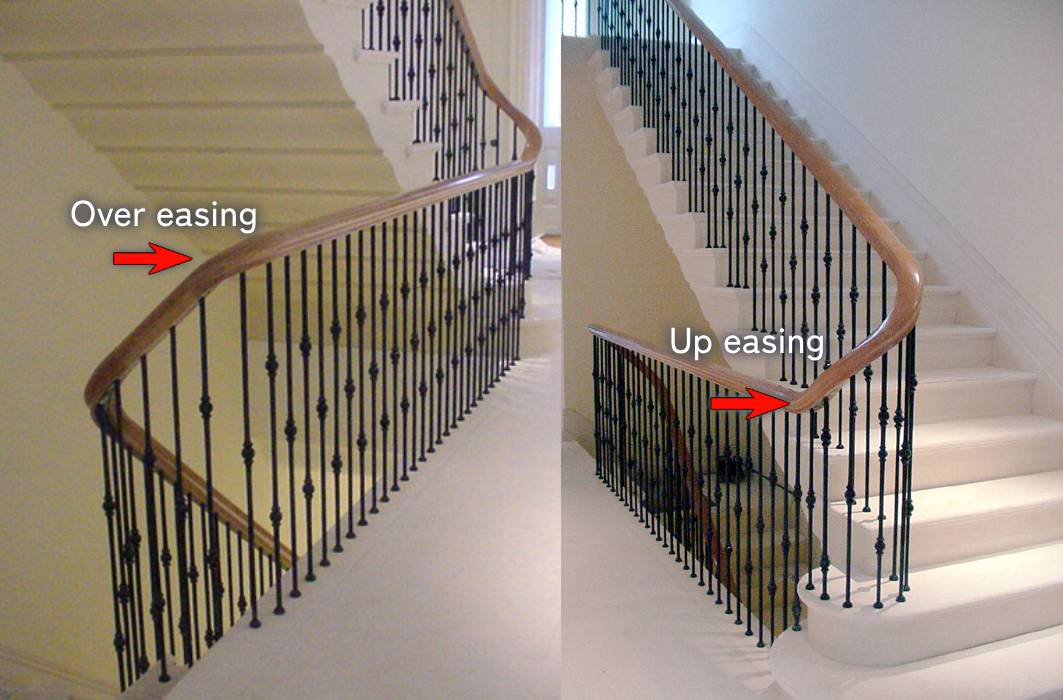

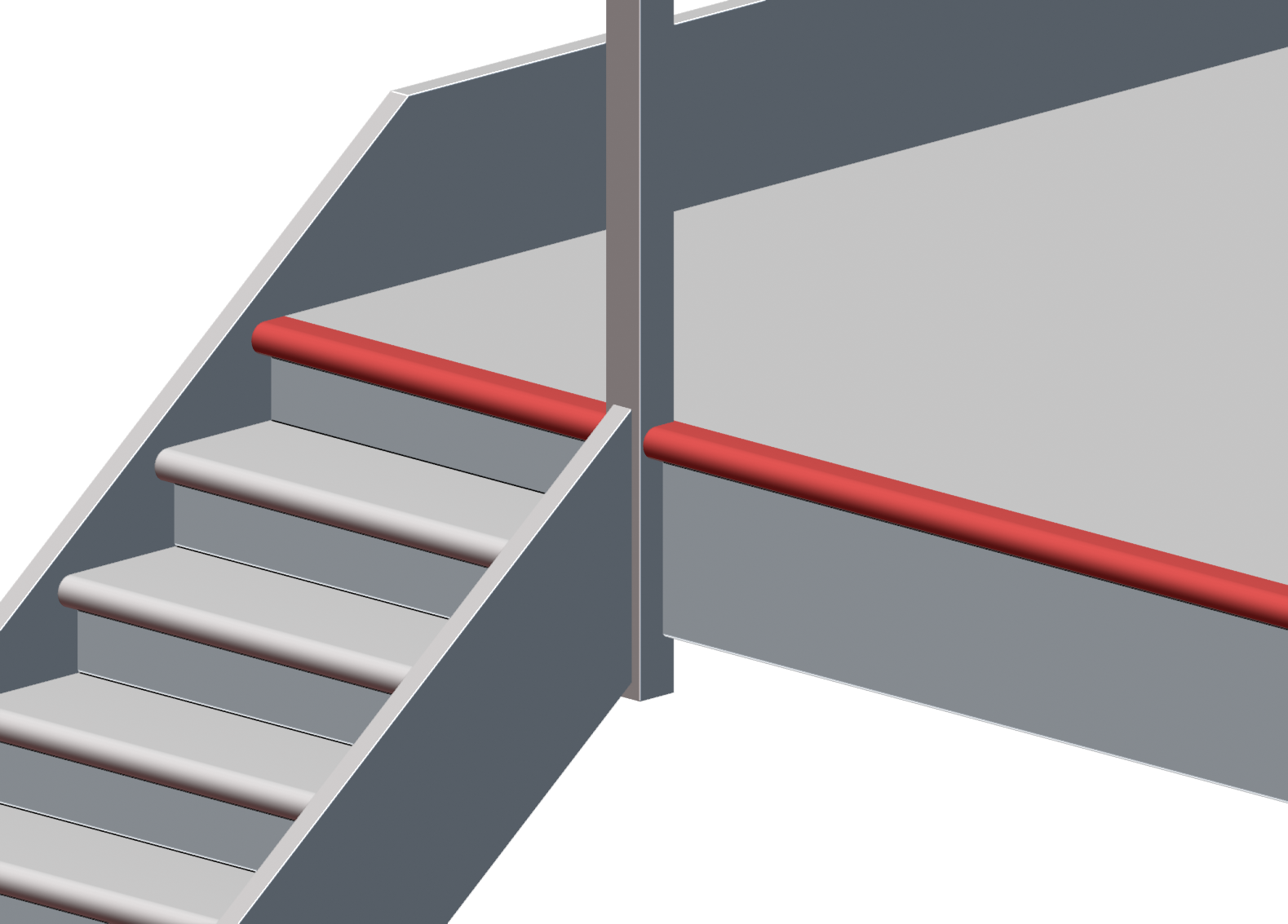

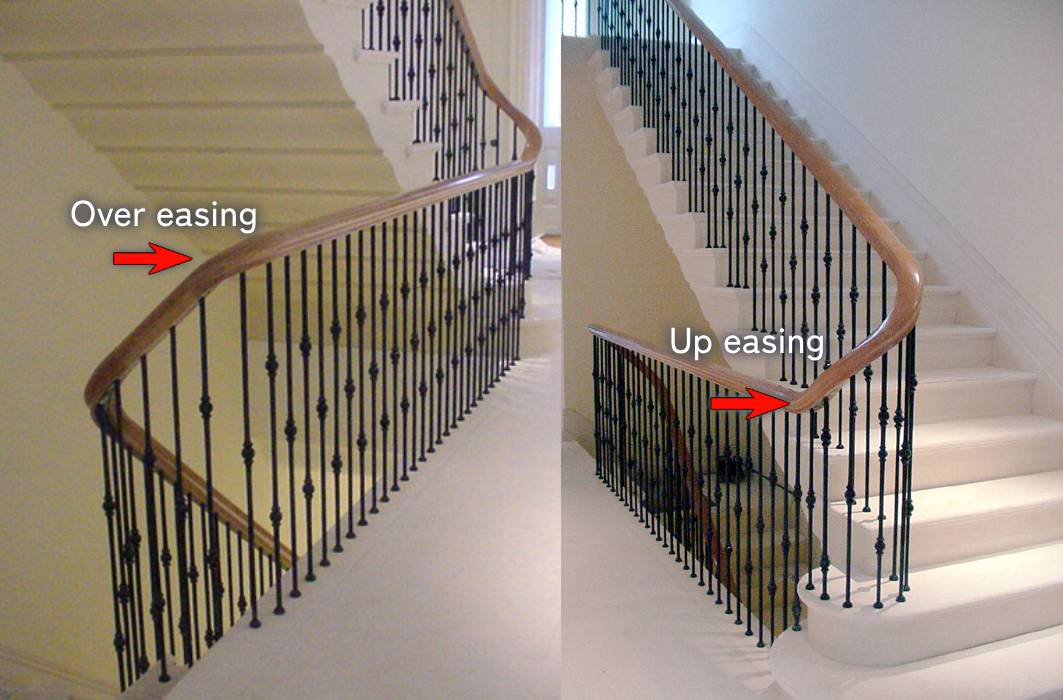

Easing

This refers to a curved transition or modification made at certain points along the handrail or balustrade. Easings are typically employed to facilitate a smooth and gradual change in direction of the handrail, allowing for a more comfortable and aesthetically pleasing staircase design.

Easings are commonly used at the top and bottom of staircases, as well as at intermediate landings or turns. They help to mitigate any abrupt angles or sharp corners that may otherwise occur when the handrail changes direction.

There are different types of easings, including volute easings and quarter-turn easings. A volute easing, for example, is a spiral-shaped element often found at the starting or ending point of a handrail, where it meets a newel post or a wall. It provides a graceful and gradual transition for the hand as it moves along the handrail.

Easings can vary in complexity and design, depending on the overall staircase style and individual preferences. They not only serve a functional purpose by enhancing the safety and comfort of using the staircase but also add an element of visual appeal and craftsmanship to the overall design.

F

Finial

Finials serve as decorative embellishments attached to the vertical sections of a balustrade.

In the case of turned spindles that are side-mounted through the return nosings, finials can be added at the bottom to complement the stringers on cut string stairs. These are more commonly found on period style cast iron staircase balustrades.

Additionally, when the newel post extends below the stringer, finials can be affixed at the bottom for added ornamentation.

It’s important to note that finials are purely decorative elements and do not contribute to the structural integrity of the banister or staircase.

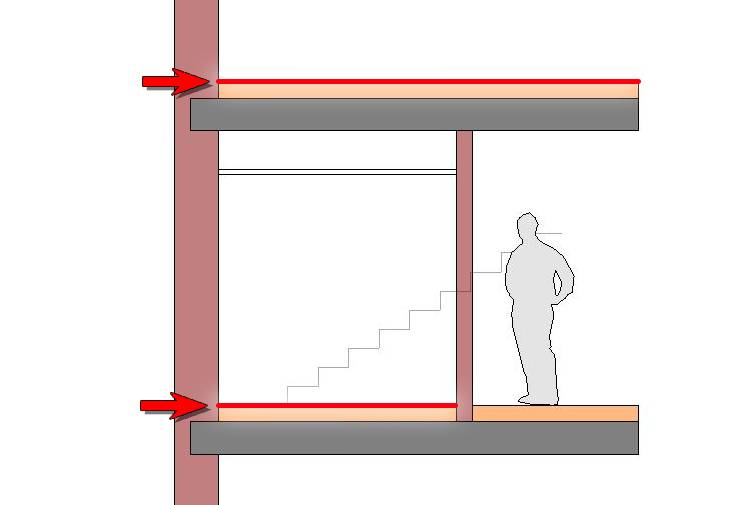

Finished Floor Level (FFL)

A finished floor level refers to the completed and finalized surface of a floor within a building or structure. It represents the topmost layer or finish applied to the structural subfloor, providing a suitable and aesthetically pleasing walking surface.

The finished floor level takes into account the desired height and material of the flooring chosen for a particular space. It can include various types of floor coverings such as hardwood, tile, carpet, vinyl, or concrete, depending on the functional and design requirements of the area.

Determining the finished floor level is essential during the construction or renovation process as it impacts the overall dimensions and alignment of doors, windows, baseboards, and of course the staircase. It is typically measured from a designated reference point, such as a benchmark or a predetermined elevation established in the building plans.

Flight of Stairs

A flight of stairs refers to a continuous series or sequence of steps that connect different levels or floors within a building or structure. It represents an uninterrupted section of a staircase, connecting one landing or floor level to another.

The main components that characterize a flight of stairs include steps (individual treads), landings (level platforms), and a continuous path for vertical movement. It is supported by structural elements such as stringers, balusters, and newel posts, which provide stability and strength.

The design and aesthetics of a flight of stairs can vary based on architectural styles, building codes, and personal preferences. Factors like the choice of materials, shape, handrail design, and balustrade style contribute to both the appearance and functionality of the flight.

Floor to Floor

Floor-to-floor measurement refers to the vertical distance between two consecutive levels or floors within a building. It represents the measurement from the finished floor level of one floor to the finished floor level of the floor directly above or below it.

The floor-to-floor measurement is an essential parameter in architectural and construction planning as it determines the overall height or vertical clearance required for proper space utilization and design. It influences factors such as the ceiling height and stairwell dimensions.

Accurate floor-to-floor measurements are crucial for ensuring that the building’s design meets functional requirements, building codes, and occupant needs. It helps architects, engineers, and construction professionals in determining the appropriate vertical spacing for various building elements and systems.

Floor-to-floor measurements can vary depending on the purpose and type of building. For instance, residential buildings typically have standard floor-to-floor heights, while commercial or industrial structures might have specific requirements based on their intended use or equipment installations.

Fluted / Flutes

Flutes, or fluted elements, refer to decorative vertical grooves which are more commonly found carved or routed into wooden spindles or newel posts.

Freestanding

A freestanding staircase, also known as a self-supporting staircase or floating staircase, is a type of staircase design that appears to be unsupported or detached from any adjacent walls or structures. Unlike traditional staircases that rely on walls or structural supports for stability, a freestanding staircase relies on its own structural elements to bear the weight and provide stability.

The defining characteristic of a freestanding staircase is its open and minimalist appearance. It creates a sense of visual lightness and elegance, often serving as a striking architectural feature in residential or commercial spaces. The absence of visible support systems gives the impression that the staircase is suspended in mid-air, adding a sense of drama and sophistication to the overall design.

Freestanding staircases can be constructed using various materials such as wood, metal, glass, or a combination of these. The treads, or steps, are typically supported by a central spine, which serves as the main load-bearing element. The spine may consist of a single structural element or a series of interconnected beams, creating a sculptural and geometric aesthetic.

To maintain stability and safety, freestanding staircases often incorporate additional structural elements, such as steel cables or rods, hidden brackets, or concealed fixings. These elements provide hidden support and ensure that the staircase remains secure and sturdy for regular use.

Due to their unique design, freestanding staircases require careful engineering and precise construction to ensure structural integrity. Professional installation by experienced craftsmen or structural engineers is often necessary to ensure compliance with safety codes and regulations.

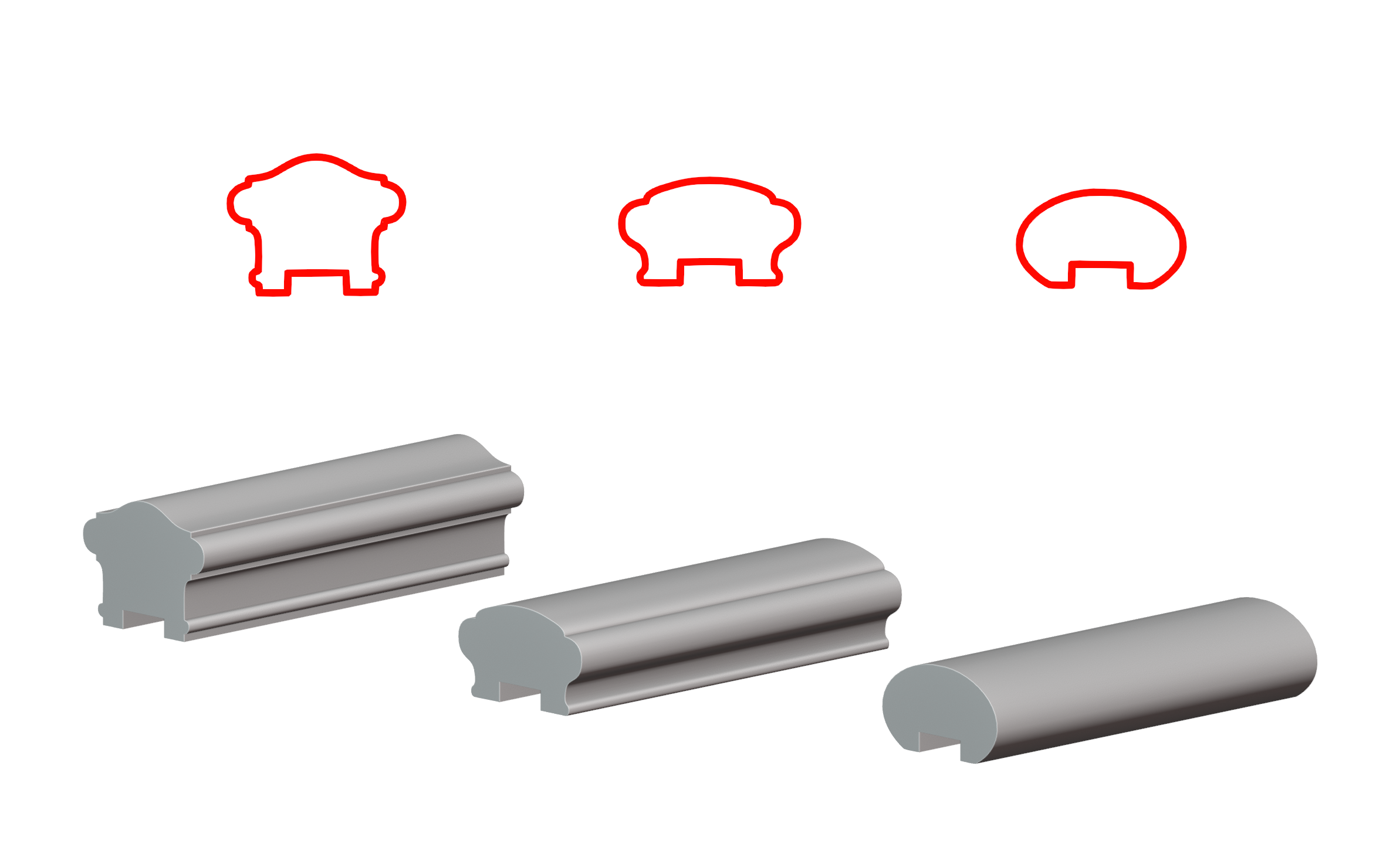

Frogs Back Handrail

This refers to a particular handrail profile. A popular choice of handrail shape as it offers a comfortable grip.

It features concave sides and a convex center, creating a distinctive shape. In some cases, the frog’s back may extend above the regular handrail profile, achieved by a quirk line, resulting in what is known as a raised frog’s back.

Full String

A full or closed stringer, also known as a solid stringer or closed string, is a type of stringer used in staircase construction. It is a solid, typically rectangular, board that runs the full length of the staircase and provides support for the treads and risers.

The closed stringer differs from an open stringer, which is constructed with a notched or cut-out design on the side that faces away from the staircase. The closed stringer, on the other hand, has a solid surface on both sides, concealing the structure of the staircase from view.

Closed stringers are commonly used in traditional staircase designs, providing a clean and finished appearance. They are typically made from a single piece of wood or other materials like metal or engineered composites.

G

Geometric

Geometric design refers to the creation of curved and ascending sections that include both treads and risers. It involves the incorporation of curved elements within the staircase structure.

A geometric handrail, on the other hand, is a handrail that follows the path of the geometric flight. It may ascend above the geometric flight, curve around corners connecting different flights, or transition from a flight to a landing area. The design of the handrail mirrors the unique shape and trajectory of the geometric staircase, complementing its aesthetic and providing support and guidance to individuals using the stairs.

Geometric staircases and handrails offer a visually appealing and dynamic element to the overall architectural design. They can be customized to suit various styles, from modern and contemporary to more traditional or ornate designs. The curved and ascending sections of the stairs, along with the accompanying handrail, create a sense of flow, elegance, and architectural interest within the space.

Glue Block

In staircase construction, glue blocks are sometimes required to enhance the strength of the joint between the tread and the riser. These blocks are typically made from a diagonal cut of a 2″ x 2″ piece, with approximately 1/8″ or 3mm of the 90º corner removed. This modification enables the block to fit snugly into the junction between the tread and riser, ensuring a secure connection without any interference from the corner.

These glue blocks are usually around 3″ or 75mm in length and are secured in place with pins or fasteners

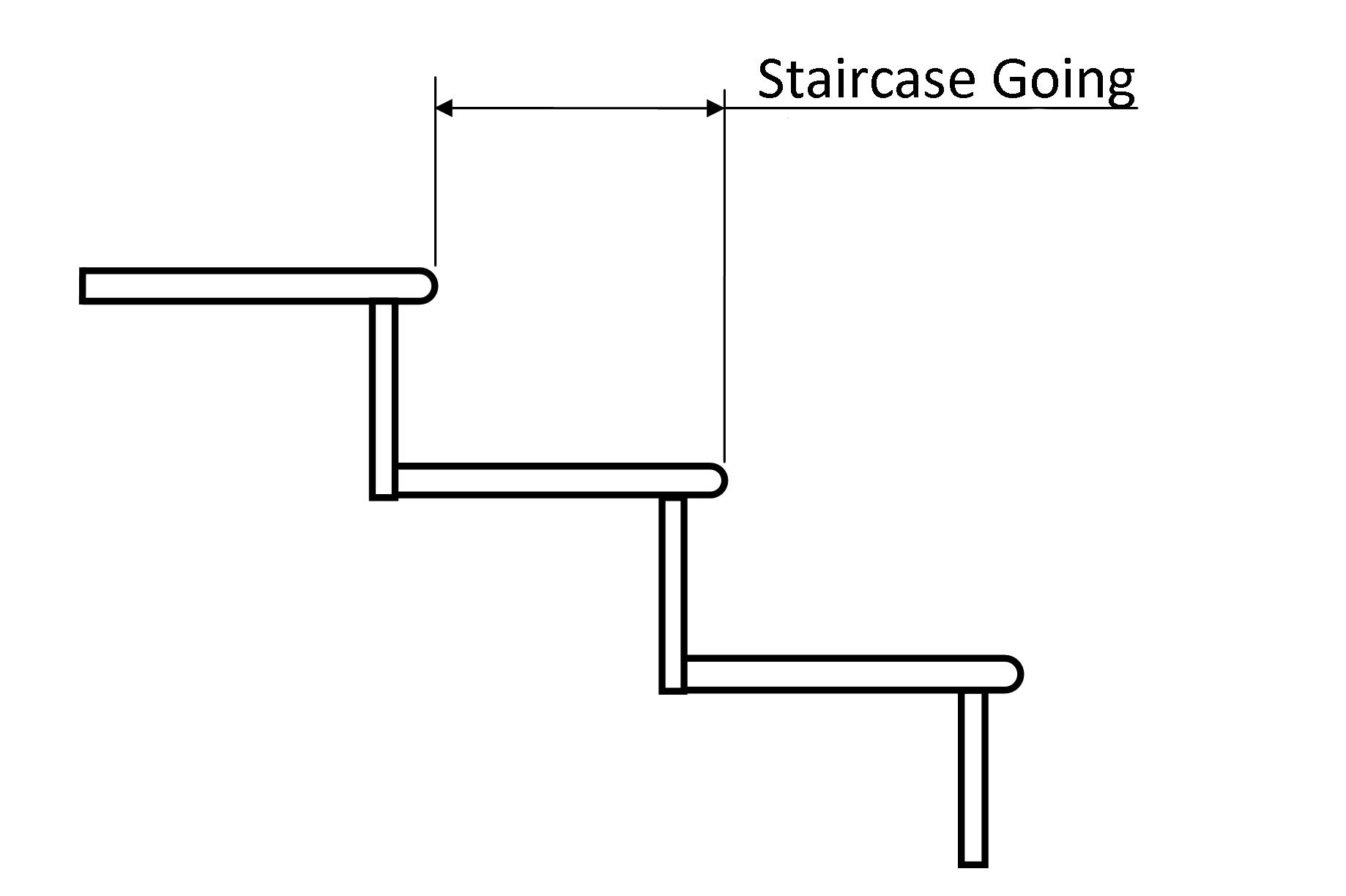

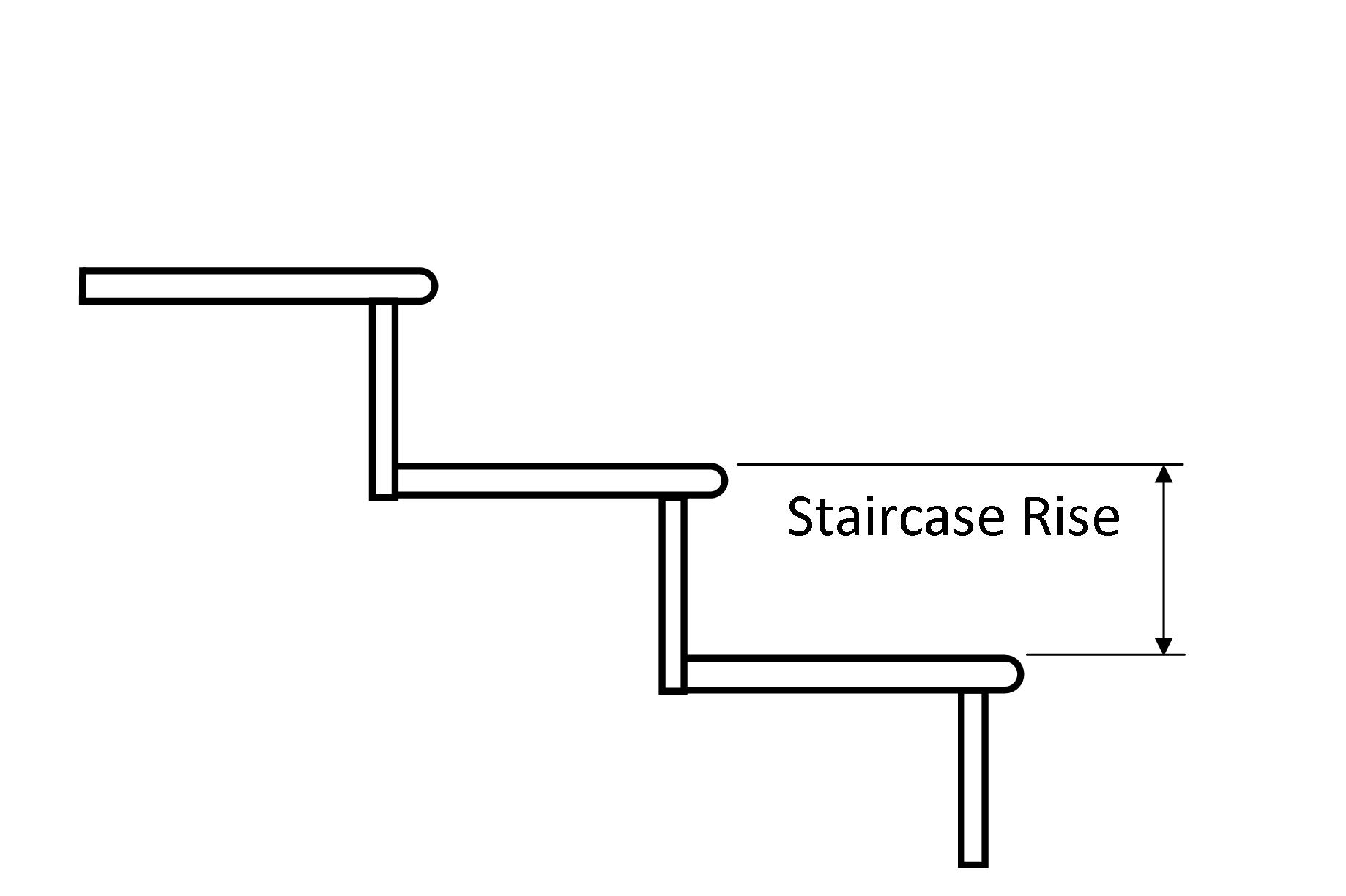

Going

This refers to the horizontal distance between two consecutive steps. It is the measurement of the depth or length of a single step or tread, from the front edge (nosing) to the back edge, where the next step begins. The going determines the amount of space available for stepping and impacts the comfort and safety of individuals using the staircase.

The going of a step is an important factor in staircase design and should comply with local building codes and regulations. It is typically standardized to ensure consistency and ease of use. The optimal going may vary depending on the building regulations and the intended purpose of the staircase. Factors such as the intended users, building occupancy, and overall design considerations can influence the specified going.

Designing the going of a staircase involves finding the right balance between usability and comfort. Steps that are too short may lead to a rapid and uncomfortable ascent, while steps that are too long can be challenging and tiring to climb. Building codes often specify the acceptable minimum and maximum going measurements to ensure safe and comfortable staircases.

Gooseneck

(see also ‘Swanneck‘)

A gooseneck or swanneck, refers to a curved section that connects a horizontal handrail to a vertical handrail or newel post. It is named after the graceful curve resembling the neck of a goose or swan.

The gooseneck or swanneck serves as a transition element between the horizontal and vertical sections of a handrail, allowing for a smooth and visually appealing connection. It is typically located at the bottom or top of a staircase where the handrail needs to change direction from a horizontal plane to a vertical plane.

The gooseneck or swanneck is designed to provide a comfortable and ergonomic grip as individuals ascend or descend the stairs. The curvature allows the hand to naturally follow the shape, ensuring a secure and supportive grip.

In terms of design, goosenecks or swannecks can vary in shape and size. They can be relatively simple and understated or elaborate and decorative, depending on the desired style and aesthetic of the staircase. The curvature can be gentle or more pronounced, adding a touch of elegance and sophistication to the overall staircase design.

Additionally, goosenecks or swannecks may incorporate other design elements such as volutes (scroll-shaped details) or embellishments that further enhance the visual appeal of the handrail. These decorative features can contribute to the overall architectural character and style of the staircase.

Grey Iron

This is the most common type of cast iron and is known for its grey color when fractured. Grey cast iron is easy to cast, has good vibration damping properties, and is often used in engine blocks, pipes, and cookware. Its graphite flakes give it its grey appearance and contribute to its ability to absorb vibrations.

H

Handrail

A handrail is a rail or bar that is typically installed along a staircase, walkway, or other elevated structure to provide support and stability to people as they move or traverse the area. It is designed to be grasped by the hand, hence the name “handrail.” Handrails are can be made in a variety of materials such as wood, wrought iron, stainless steel, brass, plastic or even glass. They are securely mounted to a wall, posts, or balusters.

They are intended to assist individuals in maintaining their balance, preventing falls or accidents, and offering a point of stability while ascending or descending stairs or navigating uneven surfaces. Handrails often comply with safety regulations and building codes to ensure accessibility and promote the well-being of users, particularly those with mobility limitations or disabilities.

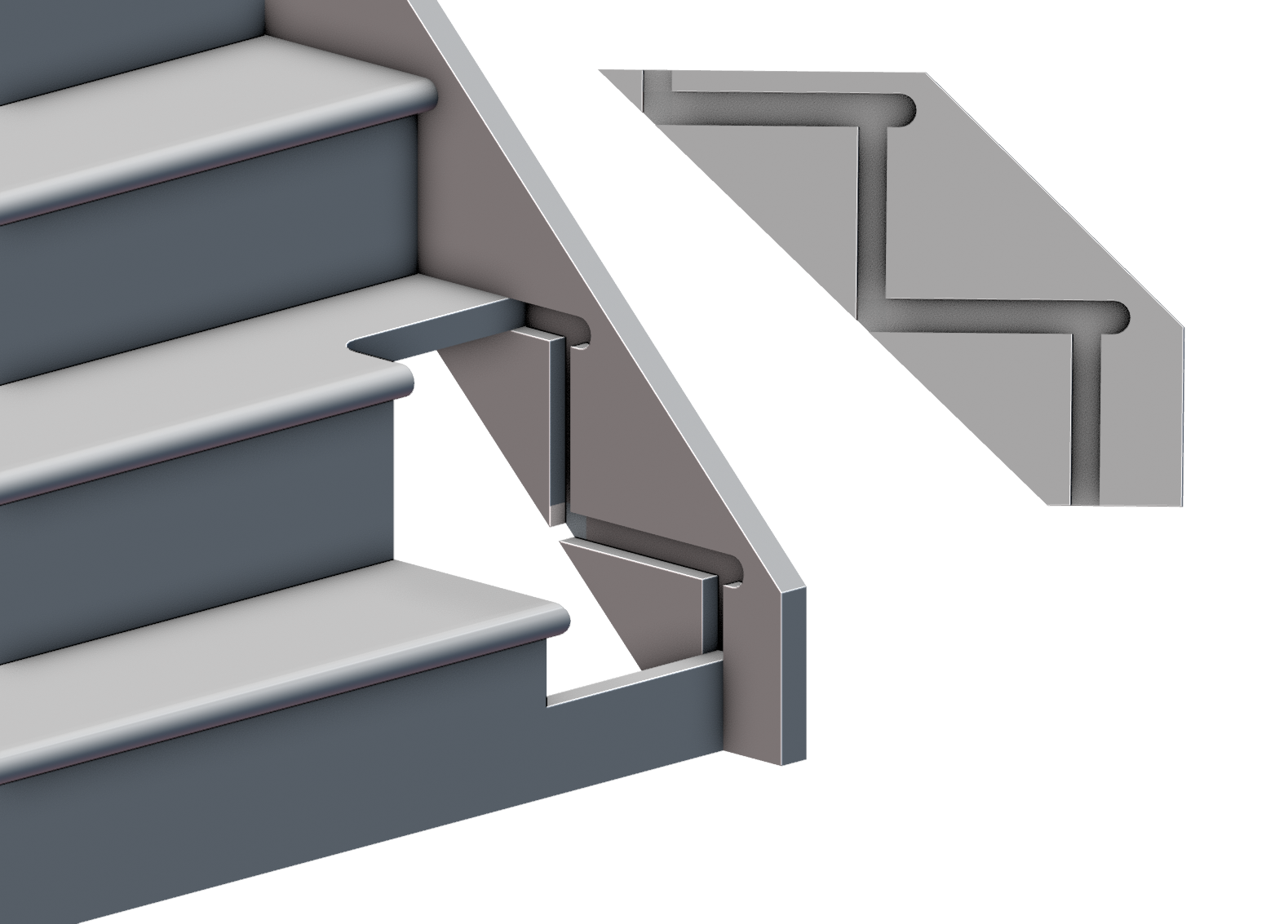

Handrail Brace

A handrail brace, also known as a handrail bracket or handrail support, is a component that provides structural support and stability to a handrail. It is typically used to attach the handrail securely to a wall or other supporting structure, ensuring its strength and integrity.

The handrail brace is designed to bear the weight and force exerted on the handrail, such as when individuals lean on or grab the handrail for support while ascending or descending stairs or walking along an elevated walkway. By securely fastening the handrail to the wall, the brace helps distribute the load and prevents the handrail from becoming loose or unstable.

Handrail braces are available in various designs and materials, ranging from simple and functional brackets to decorative and ornate supports that enhance the overall aesthetic of the handrail. They are typically made of durable materials like metal (such as steel or aluminum) or strong polymers, ensuring the necessary strength and longevity.

During installation, handrail braces are positioned at regular intervals along the length of the handrail, providing consistent support and preventing sagging or bending. The specific spacing and placement of the braces may depend on local building codes or safety regulations.

Overall, handrail braces are essential components that contribute to the overall stability, safety, and functionality of a handrail system. They play a crucial role in ensuring that handrails can effectively support individuals as they move along staircases, walkways, or any elevated areas, promoting stability and preventing accidents.

Handrail Profile

A handrail profile refers to the shape or design of the cross-section of a handrail. It plays a significant role in both the functionality and appearance of the handrail. Different handrail profiles offer unique aesthetics and functional characteristics.

One common handrail profile is the round shape, featuring a circular cross-section. It is a classic choice, providing a smooth and comfortable grip. Oval profiles combine the advantages of a round shape with flattened top and bottom surfaces, offering both comfort and a sleek look.

Square profiles have straight edges and a square-shaped cross-section, giving a modern and geometric aesthetic. Rectangular profiles, similar to square ones, have longer sides and shorter top and bottom edges. They provide a streamlined and minimalist appearance.

D-shaped handrail profiles have a flat back and a curved front, resembling the shape of the letter “D.” This design allows for a secure grip and is commonly used in commercial spaces. Additionally, custom profiles can be created to suit specific design preferences, incorporating intricate patterns, decorative elements, or ergonomic considerations.

When selecting a handrail profile, it is essential to consider factors such as comfort, safety, and the overall design context. The chosen profile should provide a secure grip, be visually appealing, and complement the surrounding environment, enhancing the overall aesthetic of the handrail installation.

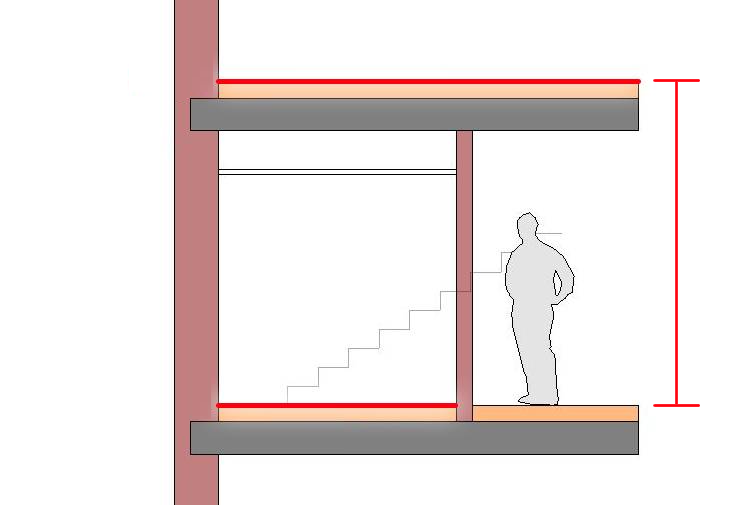

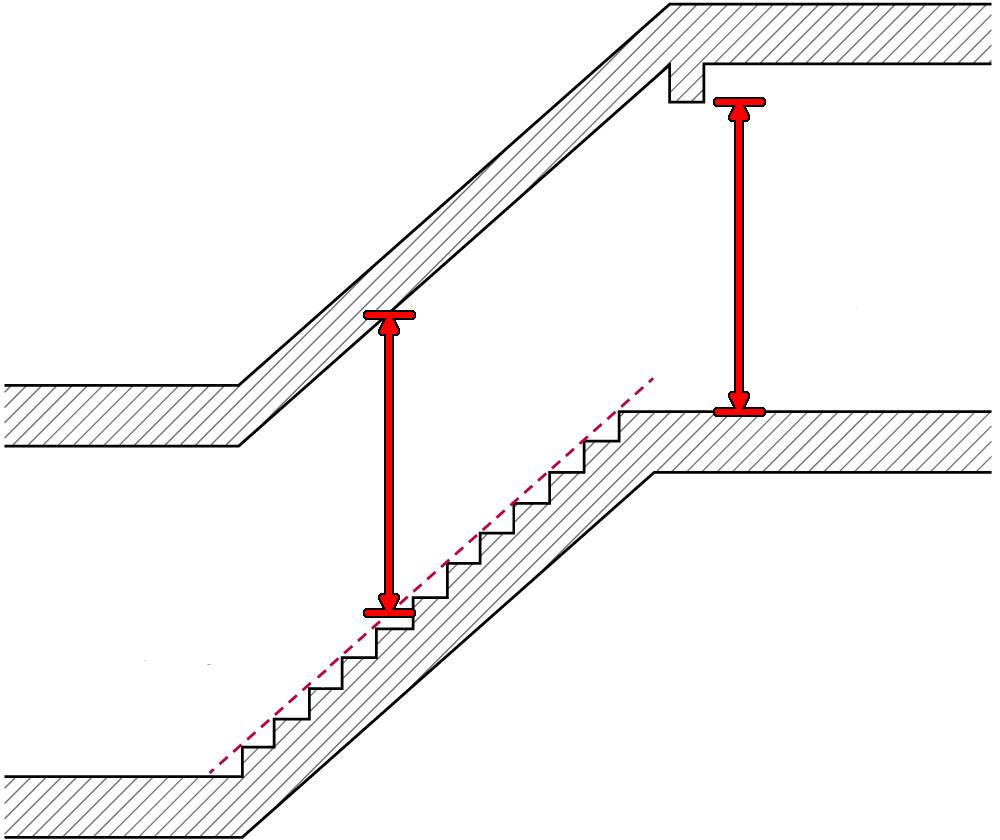

Headroom

Headroom refers to the vertical measurement from the lowest point of the ceiling above the staircase to the front edge of the tread nosing. It is a critical factor in meeting the requirements of current Building Regulations. Adequate headroom is necessary to ensure safe and comfortable passage on and off the staircase, as well as while descending the staircase.

Compliance with Building Regulations typically dictates that a minimum headroom of 2 meters (6 feet 6 inches) is required at all points along the staircase, including the top and bottom landings. This ensures sufficient clearance for individuals using the staircase, preventing any potential collisions with the ceiling or feeling of constraint.

By adhering to these regulations, staircases provide users with ample space and freedom of movement, reducing the risk of accidents and promoting a comfortable stair-climbing experience.

Helical Staircase

A helical staircase takes its name from its similarity to a helix. It can often be confused with a spiral staircase and whilst the two are similar in shape, there is a key difference – a spiral staircase winds around a central column, whereas a helical staircase winds around a void.

One of the key advantages of a helical staircase is its eye-catching visual appeal. The graceful curvature and seamless flow of the steps create a sense of elegance and sophistication. Additionally, helical staircases often become focal points within a space, serving as architectural masterpieces that elevate the overall ambiance.

Helical staircases are commonly found in residential homes, commercial buildings, and historical structures. They provide a functional means of vertical circulation while adding a touch of architectural brilliance to the surrounding environment.

I

Infil Strips

Infill strips, also known as fillets, are slender wooden strips used to fill the grooved spaces between spindles in the baserail and the underside of the handrail. These strips are inserted to create a seamless and visually appealing appearance, while also providing structural support to the staircase railing system.

J

Jig

A jig refers to a specialized tool or device used to guide, hold, or support a workpiece during various machining, shaping, or assembly operations. Jigs are designed to ensure accuracy, repeatability, and efficiency in metalworking processes.

Jigs can take various forms depending on the specific metalworking operation. They can be simple, such as a basic drilling jig with guide holes, or more complex, like a multi-component fixture with multiple points of support and alignment.

Jointing Clip

A jointing clip, also known as a handrail connector or handrail bracket, is a hardware component used to join two sections of a handrail together securely. It is designed to provide structural support and stability at the joint, ensuring the handrail remains firmly connected.

Handrail jointing clips typically consist of two main components: a bracket or plate and a connecting bolt. The bracket is usually made of a durable material such as metal or plastic and is designed to attach to the underside or side of the handrail sections. It often has holes or slots to allow for the insertion of screws or bolts.

The connecting bolt is a threaded rod or screw that passes through the holes in the bracket, connecting the two handrail sections together. It is tightened securely to hold the joint firmly in place. Some handrail jointing clips may have additional features such as locking mechanisms or adjustable angles to accommodate different handrail configurations.

The handrail jointing clip is typically installed during the construction or installation of the handrail system. It provides a strong and stable connection between two handrail sections, ensuring the overall safety and integrity of the handrail. Additionally, it helps maintain a continuous and seamless appearance along the handrail, providing a smooth transition between sections.

Jointing Compound

This refers to a specific type of compound or adhesive used for joining or securing different components of the balustrade system together.

When it comes to balustrade installations, there are various methods and materials used for joining or connecting the different components. Jointing compound or adhesive can be used to ensure a secure and stable connection between elements such as handrails, newel posts, or balusters.

The specific type of jointing compound used in balustrade installations can vary depending on the materials being joined. Jointing compounds suitable for metal balustrades may include specialized adhesives or epoxy compounds designed for bonding metals together. These compounds often offer high strength and durability to withstand the loads and stresses on the balustrade.

L

Landing

A landing is a horizontal platform or area that provides a resting point or transition between flights of stairs or between a flight of stairs and another level or floor. It is a flat surface where individuals can safely pause, change direction, or access different parts of a building.

Landings are typically located at the top or bottom of a flight of stairs, as well as at intermediate points along a staircase in multi-story buildings. They offer a space for individuals to navigate turns, enter or exit staircases, or take a break while ascending or descending.

The size and design of a landing can vary depending on the building’s design, local building codes, and the specific requirements of the staircase. Generally, landings should provide sufficient space for people to stand comfortably and maneuver, allowing for safe and convenient movement.

In addition to their functional purpose, landings can also serve as design features within a staircase. They can be customized with decorative elements, such as railings, balustrades, or flooring materials, to enhance the aesthetics and overall architectural style of the staircase and surrounding area.

Landings play a crucial role in ensuring the safety and usability of staircases. They provide a level surface where people can transition between different sections of a building or take a break during stair traversal. Proper design and construction of landings are important to comply with building regulations and create a comfortable and secure staircase experience.

Landing Nosing

Also known as a landing tread or landing edge, this refers to the front edge or protruding lip of a landing platform in a staircase. It is the part of the landing that extends slightly beyond the vertical riser, creating a visible and tactile edge.

Similar to the nosing of individual steps in a staircase, the landing nosing serves several purposes. It provides a visual cue and tactile indicator, helping individuals perceive the edge of the landing and providing a sense of depth perception as they navigate the staircase. The nosing also adds an extra level of safety by reducing the risk of tripping and providing a secure foothold.

The design and construction of landing nosings may vary depending on local building codes and architectural preferences. They are often made of a durable material, such as metal or hardwood to withstand regular foot traffic and maintain their structural integrity over time.

Landing nosings can be designed in different shapes and profiles. They may have a rounded, bullnose profile, a squared-off profile, or a custom profile that complements the overall staircase design. The choice of nosing profile can impact the aesthetics of the landing as well as the comfort and safety of individuals using the staircase.

M

Mild Steel

Mild steel, also known as low carbon steel or plain carbon steel, is a commonly used form of carbon steel. It is an iron alloy that contains a relatively low amount of carbon, usually less than 0.3% by weight. The term “mild” refers to its relatively low carbon content compared to other types of carbon steel.

Mild steel’s combination of strength, ductility, weldability, and affordability makes it a popular choice for a wide range of applications where moderate strength and formability are required. It is used in structural components, architectural ironwork, machinery parts, automotive frames, pipes, sheet metal, and many other products that benefit from its versatility and ease of fabrication.

Monkey Tail

(see also Volute)

A monkey tail volute is a specific design element found in the handrail of a staircase. It is characterized by its unique and distinctive shape, resembling the curl of a monkey’s tail or a spiral. A monkey tail would typically be located at the starting or ending point of a handrail where it connects to a newel post.

The design of the monkey tail combines an elegant curve with intricate detailing, creating a visually striking feature in staircase design. It adds a touch of sophistication and decorative flair to the overall aesthetic of the handrail and staircase.

The monkey tail can be made in a variety of materials such as wood, stainless steel, bronze, cast iron etc. To craft this requires precision and attention to detail to create the smooth, flowing curves that resemble the graceful curve of a monkey’s tail.

While the monkey tail volute is primarily a decorative element, it also serves a practical purpose by providing a comfortable and ergonomic hand grip as individuals ascend or descend the staircase. The shape of the volute allows the hand to naturally follow its contours, ensuring a secure grip and a pleasant tactile experience.

Monkey tail volutes can be found in various staircase designs, ranging from traditional and classical styles to more contemporary and modern interpretations.

Mould/Mold

A casting mold, also known as a foundry mold or simply a mold, is a cavity or container designed to shape and form molten material into a desired solid object through the casting process.

Casting molds are essential in various industries, including metal casting, plastic molding, glass blowing, and ceramics. They enable the production of complex shapes, precise dimensions, and intricate details in a range of finished products, from cast iron balustrades, gates and railings to automotive parts, machinery components and artistic sculptures and decorative items.

N

Newel Base

A newel base, also known as a newel post base or bottom newel, refers to the lowermost part of a newel post in a staircase. It is the structural component that provides stability and support to the newel post, connecting it to the staircase structure or the floor below.

The newel base is typically a larger and wider section compared to the rest of the newel post. It serves as the foundation upon which the newel post rests, ensuring it remains securely in place. The design and construction of the newel base can vary depending on the specific staircase design, building materials used, and architectural style.

Newel bases are commonly made from solid wood, although other materials such as metal or stone can also be used. They are often crafted to match or complement the overall design of the newel post and the staircase. Decorative elements or carvings may be incorporated into the newel base to add visual interest and align with the aesthetic theme of the staircase.

Newel Cap

(see also Finial)

A newel cap, also referred to as a newel post cap or finial, is a decorative element that sits on top of a newel post in a staircase. It serves as a finishing touch to the newel post, adding a decorative accent and completing the overall look of the staircase design.

Newel caps come in a variety of shapes, sizes, and materials, allowing for customization and coordination with the overall style of the staircase. They can be simple and understated or elaborate and ornate, depending on the desired aesthetic.

The primary function of a newel cap is to provide a polished and refined appearance to the top of the newel post. It adds a decorative focal point, often featuring intricate carvings, patterns, or motifs that reflect the architectural style or theme of the staircase.

Newel caps may be crafted from various materials such as wood, metal, stone, or even glass, depending on the desired look and the materials used throughout the staircase. The choice of material can contribute to the overall durability, aesthetic appeal, and maintenance requirements of the newel cap.

In addition to their decorative role, newel caps can also provide functional benefits. They help protect the top of the newel post from wear and damage, preventing splintering or scratches that may occur over time.

Newel Drop

(see also Finial)

The newel drop is a decorative embellishment installed at the lower end of a newel post that extends beyond the ceiling line. It serves to enhance the visual appeal and aesthetic continuity of the staircase design.

Newel Post

A newel post is a vertical structural element in a staircase that provides support and stability to the handrail system. It is a large, sturdy post that is typically located at the beginning, end, and sometimes at intermediate points of a staircase.

The newel post is an integral part of the staircase’s design and construction. It is usually larger and more prominent than the other posts or balusters in the railing system. Newel posts can be made of metal, wood or other durable materials such as stone, depending on the desired style and structural requirements.

The primary functions of a newel post are to support the handrail, provide stability to the staircase, and serve as an anchor for the balusters or spindles. It also acts as a visual focal point and can feature decorative elements such as carvings, finials, or other ornate details that enhance the overall aesthetic of the staircase.

Newel posts come in various shapes, sizes, and styles to suit different architectural designs and personal preferences. They can be square, round, fluted, or feature custom profiles, depending on the desired aesthetic and the architectural style of the staircase and the surrounding space.

Nosing

A nosing is the protruding edge of a step or tread that extends beyond the riser (vertical portion) of the step. It is the part of the step that is typically rounded or beveled to create a smooth transition between the tread and the riser.

The nosing serves several important purposes. Firstly, it provides a visual and tactile indicator, allowing individuals to perceive the edge of each step as they ascend or descend the staircase. This helps improve safety by reducing the risk of trips and falls.

Secondly, the nosing adds structural integrity to the step by providing additional support and preventing the front edge of the tread from wearing or splintering over time. It helps distribute the weight of foot traffic evenly across the step and enhances its durability.

The design of the nosing can vary depending on regional building codes and personal preferences. It can be a rounded bullnose profile, a square-edged profile, or a custom profile that complements the overall style of the staircase. The choice of nosing profile may also affect the comfort and ergonomics of using the staircase.

Nosing materials can include metal, wood, stone, or other suitable materials. They are typically chosen for their durability and resistance to wear, as they are subjected to regular foot traffic.

O

Open Risers

This is a design feature in a staircase where there is a visible space or gap between adjacent treads, leaving the vertical risers exposed. Unlike closed risers, which have a solid, continuous surface between each step, open risers create an open, airy look and allow for transparency and light flow through the staircase.

Open riser staircases offer a few distinct advantages and aesthetic qualities. Firstly, they create a sense of openness and spaciousness in the surrounding area. The gaps between the treads allow light to pass through, making the staircase feel less visually imposing and creating a more contemporary and modern look.

Additionally, open risers can contribute to the overall design and architectural style of a space. They offer opportunities for creative and unique staircase designs, as the exposed risers can be customized with various materials, finishes, or decorative elements. Open risers also promote an uninterrupted view of the staircase, enhancing the visual appeal and architectural interest.

However, it’s important to note that open riser staircases may have specific building code requirements to ensure safety. Regulations often specify the maximum size of the gap between treads to prevent accidents and ensure that users, especially children, cannot easily slip through or get their feet stuck. Local building codes should be consulted and followed to ensure compliance and safety.

P

Patina

Patina refers to a thin layer that forms on the surface of certain materials, particularly metals, as a result of natural aging, exposure to the environment, or deliberate chemical treatments. It is a gradual and often desirable transformation that occurs over time, adding character, depth, and visual appeal to the surface.

Metal surfaces, such as copper, bronze, brass, and iron, are particularly known for developing patina. Over time, metals react with oxygen, moisture, and other elements in the atmosphere, resulting in the formation of a thin layer on the surface. This layer often exhibits unique colors, textures, and patterns, giving the metal an aged or weathered appearance (see Patination below for more information).

Patination

Metal patination refers to the process of intentionally aging or altering the surface of metal objects to achieve desired colors, textures, or finishes. It involves the application of various chemicals, heat, or physical techniques to produce a patina—a thin layer that forms on the metal’s surface through oxidation or corrosion.

Patination allows craftsmen to create the appearance of age, weathering, or a specific artistic style on metal objects. The patina can range from subtle, natural-looking shades to vibrant, vivid colors.

Different metals, such as copper, bronze, brass, and silver, exhibit unique patina characteristics. Copper, for instance, develops a characteristic greenish patina known as verdigris over time when exposed to moisture and atmospheric agents. Bronze can develop various shades of brown, green, or blue, while brass can develop a range of yellow, brown, or reddish hues. Silver often develops a tarnished black patina.

There are several methods to achieve metal patination. Some common techniques include:

- Chemical Patination: This involves applying chemical compounds, such as acids, salts, or oxidizers, to the metal’s surface. These chemicals react with the metal, causing it to oxidize and form a patina. The choice of chemicals and their application method determines the resulting color and texture.

- Heat Patination: Heat can be used to alter the color and surface of metal. By heating the metal to specific temperatures, different oxides or coatings can be formed, resulting in a desired patina. Heat patination is often used on copper, where a torch or kiln is employed to achieve distinctive colors.

- Mechanical Patination: This technique involves physically altering the metal’s surface through abrasion, brushing, polishing, or hammering. These actions can create textures, patterns, or variations in the metal’s appearance, mimicking natural wear and tear.

- Natural Patination: Sometimes, metal objects are left exposed to the elements to naturally develop a patina over time. This method takes advantage of environmental factors like moisture, humidity, sunlight, and air pollutants to cause gradual oxidation and patina formation.

At Fine Iron we have our very own in house patination room and have a few select craftsmen who are professionally trained in the art of patination.

Pattern

A pattern is a replica or model used in the casting process to create the mold cavity into which molten material will be poured or injected. It serves as a template or guide for shaping the mold and achieving the desired final form of the cast object.

The primary purpose of a casting pattern is to provide a precise representation of the desired final object. It defines the shape, size, and details of the cast component, including any complex features, cavities, or undercuts.

Patterns can be made from various materials depending on factors such as the casting process, the material being cast, and the desired level of accuracy and durability. Common pattern materials include wood, metal, plastic, and wax. They are designed based on engineering drawings or specifications for the intended cast object and are typically constructed to accommodate the shrinkage and other factors inherent in the casting process. Patterns may consist of multiple components, such as a main body and detachable sections, to facilitate mold removal and core placement.

Patterns can be classified into various types based on the casting process and purpose. Some common pattern types include single-piece patterns, split patterns, matchplate patterns, and core boxes. Each type has specific design considerations and is suited to different casting methods.

Patterns are constructed with dimensional allowances to compensate for shrinkage, machining or finishing requirements, and the expected properties of the cast material. These allowances ensure that the final cast object meets the desired specifications after casting and any subsequent machining or surface treatments.

Making a pattern involves various techniques, including woodworking, metalworking, or using 3D printing technologies. Skilled pattern makers create or replicate patterns with high precision to achieve accurate and consistent castings.

Casting patterns play a crucial role in the casting process by enabling the creation of mold cavities that accurately replicate the desired object. They serve as essential tools in industries such as foundries, metal casting, and prototyping, ensuring the production of high-quality and precise cast components.

Pig Iron

Pig iron is an intermediate product in the iron and steel production process. It is the result of smelting iron ore with a high-carbon fuel, such as coke, usually in a blast furnace. Pig iron is the crude form of iron that is extracted from the furnace before further refining and processing to create various types of steel and iron products.

Pig iron typically contains a relatively high amount of carbon, usually in the range of 2% to 4%. It also contains impurities such as sulfur, silicon, manganese, and phosphorus, which are present in the iron ore and coke used in the smelting process. It has a grainy appearance and is usually cast into molds called pigs, which is where its name originates. These pigs are relatively large blocks or ingots with irregular shapes.

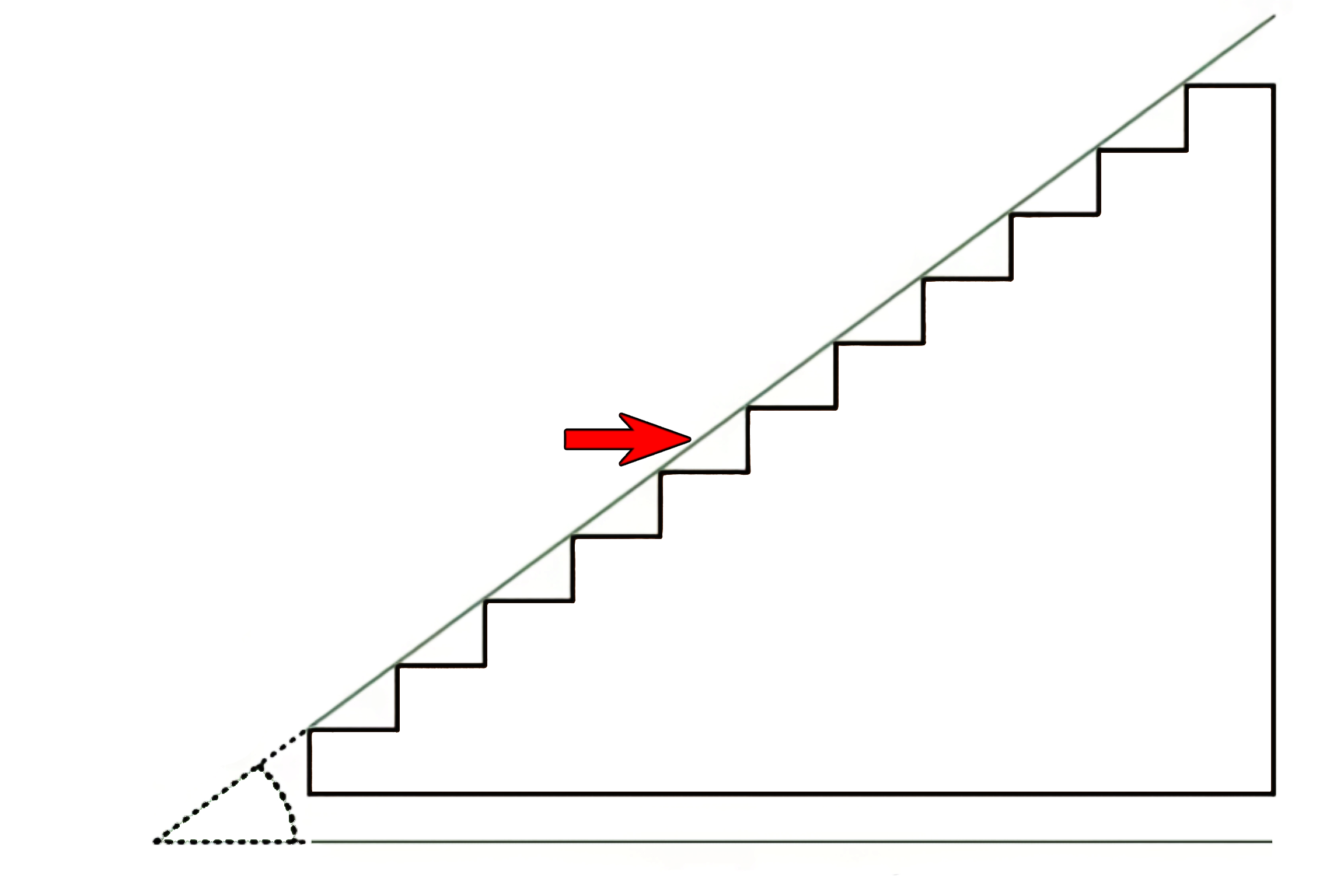

Pitch

Pitch refers to the angle or slope of the staircase. It is a measure of how steep or shallow the staircase is in relation to the horizontal plane. The pitch is typically expressed as a ratio or a percentage.

The pitch of a staircase is determined by the rise (vertical height) and the going (horizontal depth) of each step. The rise is the vertical distance between two consecutive treads, while the going is the horizontal distance from the front edge of one tread to the front edge of the next tread.

The pitch of a staircase influences the overall comfort, safety, and usability of the stairs. A steep pitch with a high rise and short going will result in a more vertical staircase, which may require more effort to climb and may not be suitable for individuals with mobility issues. On the other hand, a shallow pitch with a low rise and long going will create a more gradual and easier-to-navigate staircase.

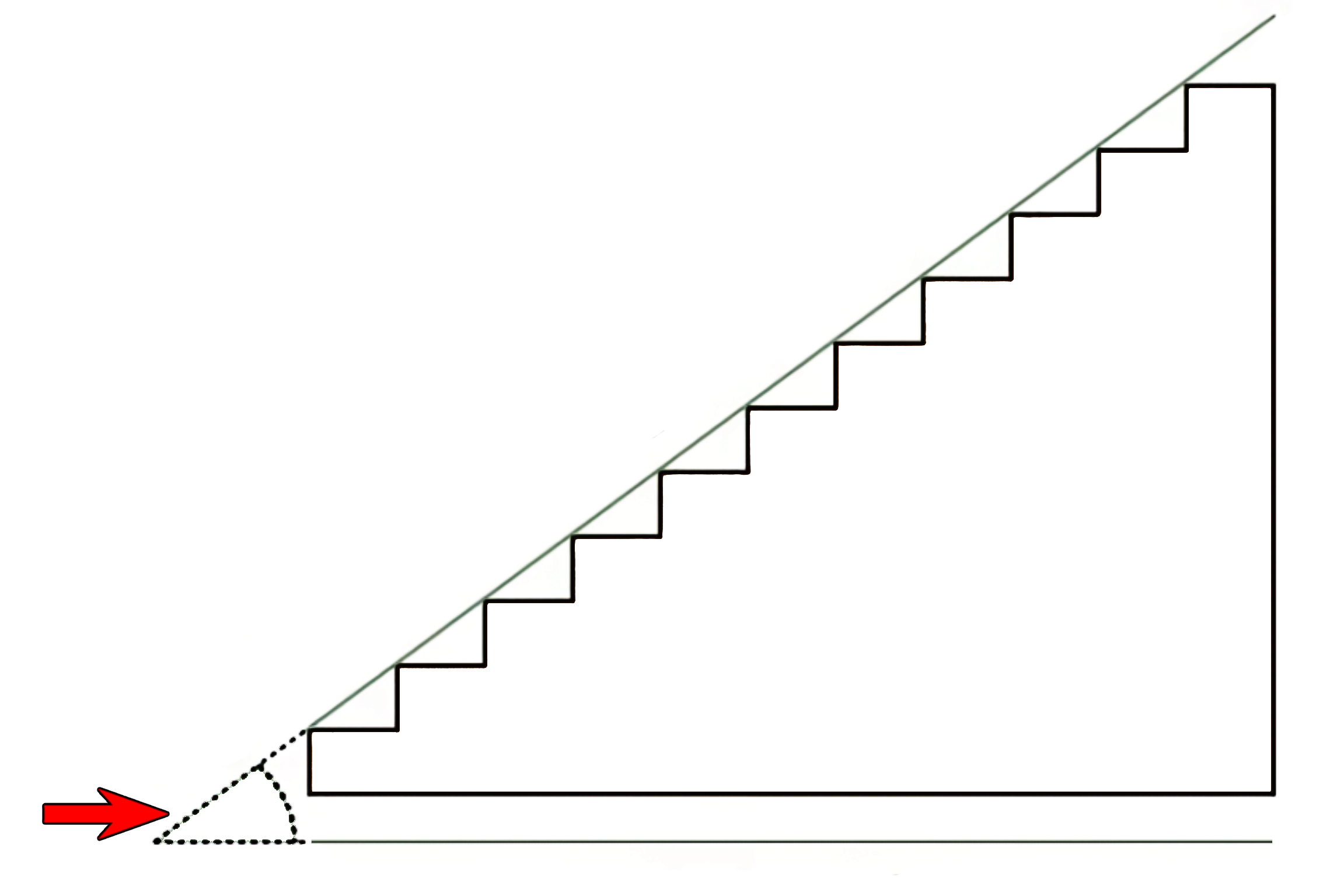

Pitch Line

The pitch line of a staircase is an imaginary line that runs along the nosings (front edges) of the treads, creating a smooth, continuous path from the bottom to the top of the staircase. It represents the trajectory or inclination of the staircase, following the rise and run of each step.